Read the full article here: https://www.mdpi.com/1424-8220/23/20/8379

In-Place-Inclinometers (IPI) are traditional continuous monitoring instruments in inclinometer tubes; in particular, Sisgeo’s “BH-Profile” (BH-Profile in-place Inclinometers – Sisgeo) are used successfully in many applications around the world.

The gained experience highlighted the need for a versatile instrument that could be housed in small tubes without the use of special guides. Sisgeo thus developed a version of fixed inclinometers called “MD-Profile” (MD-Profile array – Sisgeo).

The MD-Profile is a patented system that consists of a continuous chain of digitised sensors (RS-485, MODBUS), connected together by means of a single metal connector that guarantees the mechanical and electrical connection. The rods are connected by a specially developed cardan joint, which on the one hand ensures the kinematic motion of the rods and on the other hand by means of bilateral centring devices keeps the pivot points and rods in a central position. This solution allows a direct correlation between the inclination of the individual instrument and the application of the classical measurement processing technique, i.e. the cumulative; the latter is therefore consistent with the displacement approximation and is not affected by additional sources of uncertainty. Furthermore, the lack of cables severely limits unwanted deformations in the measurement chain.

The direct output of each instrument in the desired engineering unit results in data transparency and allows easy integration into any data logger. The low weight simplifies transport and installation in the field. Each sensor comes with a Calibration Report certifying its accuracy performance.

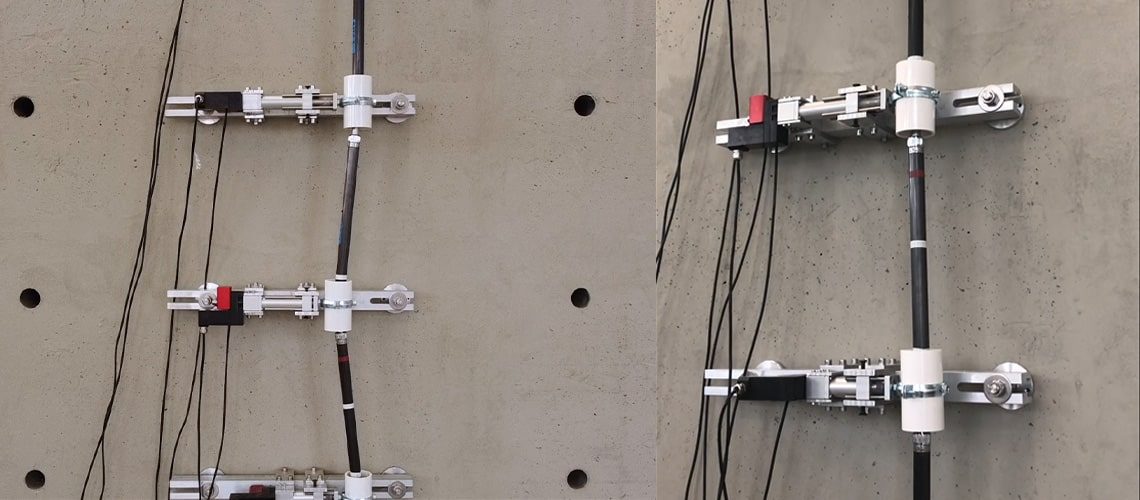

The new features introduced required validation, which was obtained by carrying out a laboratory test campaign on the individual instruments and, as a great novelty, on the entire measurement chain. During the tests, controlled simulations of possible real application scenarios (diaphram walls, landslide areas, etc.) were carried out, recreating a set-up capable of moving both axes of known quantities. This was possible thanks to the collaboration with Prof. Francesco Freddi of the University of Parma. First of all, an ad-hoc test set-up was developed to assign a movement to each node of the measurement chain. Subsequently, an extensive validation test campaign was carried out at the University of Parma, which allowed the determination of the maximum error, repeatability, cumulative displacement error and disturbance on instruments not involved in the movement. The study made it possible to assess not only the stability but also the performance of the entire measuring chain, not limiting to the individual measuring element.

The development experience was the subject of a scientific publication in an international journal, in which the main characteristics of the instrumentation are illustrated and the results of the validation tests carried out on prototypes and pre-production samples at the University of Parma are summarised.

Currently, the system has already been successfully installed in several projects such as the Renaix Tunnel in Belgium or Eraring dam in Australia.

With this system, Sisgeo is at the forefront of metrology for fixed inclinometer chain applications, thus consolidating its technological leadership.