Giovanni Caloni1 and Luca Besana2

1 M.Sc Environmental Engineer, SISGEO Srl, Via F. Serpero 4/F1 – Masate-Milan, ITALY

2 Mechanical Engineer, SISGEO Srl, Via F. Serpero 4/F1 – Masate-Milan, ITALY

Abstract. Dams are critical infrastructures that require continuous monitoring to prevent structural failure and ensure long-term stability. Many existing dams, however, rely on outdated manual monitoring systems, resulting in inefficiencies in data collection and analysis. This paper explores the rehabilitation and optimization of structural health monitoring (SHM) systems of some existing dams in Uzbekistan, emphasizing the integration of modern technologies with pre-installed instrumentation.

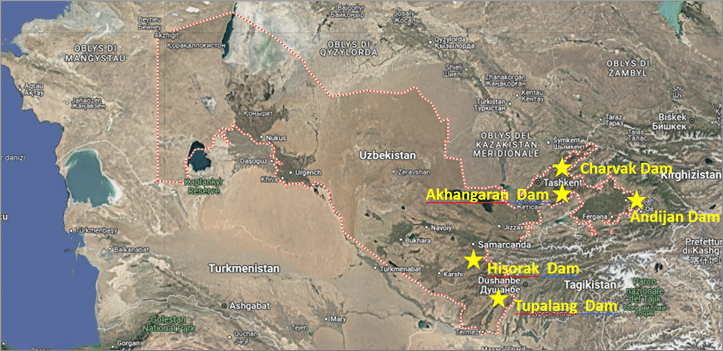

The evaluation phase includes reviewing operational and non-operational instruments, verifying the quality of existing sensors, reviewing data acquisition methods, and determining the feasibility of automation. Case studies from Uzbekistan, including the Charvak, Akhangaran, Hisorak, Andijan, and Tupalang dams, illustrate successful implementations of upgraded SHM systems. These upgrades involved the integration of automated wired and wireless data loggers, the installation of new sensors such as piezometers, tiltmeters, crackmeters, tele-pendulums, and the implementation of remote access for real-time data visualization.

Automation of existing instrumentation has improved data accuracy, reduced manual labor, and enabled nearly-real-time alerts to be received in case of abnormal conditions. Installation of new equipment has filled monitoring gaps, improving the overall safety and operational efficiency of the barrage facilities. Integration of historical data with automated systems has improved trend analysis and early detection of anomalies.

Challenges such as compatibility between old and new tools, budget constraints, data management, cybersecurity, and staff training were also discussed. This paper finally concludes that modernization of dam SHM systems improves safety and decision-making capabilities. Future advances in IoT and AI-driven analytics are expected to further revolutionize dam monitoring, ensuring resilience against structural hazards.

Keywords: Dam Rehabilitation, Dam Structural Health Monitoring, Dam Safety, Dam Instrumentation, Instrument Automation

1 Introduction

Dams are essential infrastructures that play a crucial role in water resource management, energy production, and flood control. However, their structural integrity must be continuously monitored to prevent catastrophic failures, ensure long-term operational stability, and maintain high efficiency. Effective monitoring not only enhances safety but also optimizes the dam’s performance by detecting inefficiencies such as leakage or mechanical wear that could reduce its effectiveness over time.

Many existing dams, particularly older structures, still rely on traditional manual monitoring methods, which can be time-consuming, inefficient, and prone to human error. These outdated techniques often fail to provide real-time insights, limiting the ability of engineers to detect early warning signs of potential structural issues and reducing opportunities for timely maintenance interventions that could sustain peak operational efficiency. The emergence of modern Structural Health Monitoring (SHM) technologies presents a transformative opportunity for improving dam safety and efficiency. Advanced sensors, automated data acquisition systems, and real-time analytics enable continuous assessment of a dam’s condition, allowing for more precise and timely decision-making. By leveraging SHM, dam operators can significantly enhance predictive maintenance strategies, reduce operational risks, and optimize resource allocation.

Despite these advancements, transitioning from traditional monitoring systems to modern SHM solutions presents several challenges. One of the primary concerns is integrating new technologies while maximizing the use of existing infrastructure and pre-installed instrumentation. Upgrading a dam monitoring system requires careful planning, including selecting appropriate sensors, establishing reliable data transmission channels, and implementing robust data analysis frameworks.

This paper explores the critical steps involved in the rehabilitation of the dam monitoring systems of five Uzbek structures: Charvak, Akhangaran, Hisorak, Andijan and Tupalang Dams.

1.1 Brief description of the dams covered by this work

The Akhangaran Dam (Ahangaran to’g’oni) is a significant earth-fill dam located on the Akhangaran River in the Tashkent region of Uzbekistan. The dam serves multiple purposes, including water supply, irrigation, and flood control, playing a crucial role in the region’s water management system.

The Hisorak Dam (Hisorak to‘g‘oni) is an earth-fill dam located in the Qashqadaryo region of southern Uzbekistan. It is built on the Hisorak River. The main purpose of the Hisorak Dam is to support farming in a dry and mountainous area by storing water during the wet season and releasing it during periods of drought. The reservoir plays a key role in improving water management and agricultural productivity in the region.

The Andijan Dam (Andijon to‘g‘oni) is an embankment dam with impervious core. It is in the eastern part of Uzbekistan, in the Andijan Region, near the border with Kyrgyzstan. It was built on the Kara Darya River and completed in the 1970s. The dam creates the Andijan Reservoir which plays a vital role in water storage for irrigation, hydroelectric power generation, and flood control. Due to its strategic location and multi-purpose functionality, the Andijan Dam is an important component of Uzbekistan’s water and energy infrastructure.

The Charvak Dam (Charvoq to‘g‘oni) is a rock-fill with concrete face dam. It is a major hydroelectric and irrigation dam located in the Tashkent Region of Uzbekistan, at the confluence of the Pskem, Kok Su, and Chatkal rivers. Completed in 1970, the dam created Lake Charvak, a large reservoir that has become a key water source for agriculture, as well as a popular recreational area. The dam is part of the larger Charvak Hydroelectric Power Station and plays an important role in generating electricity for the region. In addition to its energy production, the Charvak Dam helps regulate river flow and supports irrigation systems that sustain farming in the surrounding areas.

The Tupalang Dam (To‘palang to‘g‘oni) is an earth-fill dam located in the Surxondaryo region in southern Uzbekistan. Built on the Tupalang River, it is one of the country’s major hydraulic structures. The dam serves several key purposes: regulating water flow for agricultural irrigation, providing flood protection, and generating hydroelectric power. With its large reservoir, the dam ensures a stable water supply crucial for the region’s agriculture. It also contributes to the local power grid through hydroelectric energy production.

- Assessment of Existing Monitoring System

Before implementing an upgrade, a comprehensive evaluation of the existing monitoring infrastructure, installed during construction, mainly in the 1960s and 1970s, is required. The key steps in this phase are described below.

- Identification of operational and non-functional instruments.

For dam monitoring rehabilitation projects, a site visit is essential to determine the installed instruments, those that are still functioning and the key instruments that are not functioning. For example, during the rehabilitation of the monitoring system of the Charvak dam, an evaluation revealed that several piezometers were still functioning but needed automation, while some gauges were no longer providing reliable data and needed to be replaced.

2 Assessment of Existing Monitoring System

Before implementing an upgrade, a comprehensive evaluation of the existing monitoring infrastructure, installed during construction, mainly in the 1960s and 1970s, is required. The key steps in this phase are described below.

2.1 Identification of operational and non-functional instruments

For dam monitoring rehabilitation projects, a site visit is essential to determine the installed instruments, those that are still functioning and the key instruments that are not functioning. For example, during the rehabilitation of the monitoring system of the Charvak dam, an evaluation revealed that several piezometers were still functioning but needed automation, while some gauges were no longer providing reliable data and needed to be replaced.

2.2 Quality testing of existing instruments

The certainty of the measurement quality of dated instrumentation is of crucial importance. The simplest test method is through comparative analysis with independent measurements or, the better way, recalibration where it is possible to remove the sensor for a check, maintenance, and calibration in metrological laboratory.

2.3 Assessment of data acquisition methods and frequency

The existing manual data collection process was reviewed, revealing inconsistencies in measurement intervals. To address this, wired and wireless automated data loggers were installed to standardize acquisition frequency and ensure continuous, reliable data collection without human intervention.

2.4 Evaluation of data reliability and historical trends

The historical data collected manually over several decades was reviewed and integrated into a centralized data management software. This allowed engineers to compare past measurements with real-time automated data, improving trend analysis and early anomaly detection.

2.5 Determination of automation feasibility for existing instruments

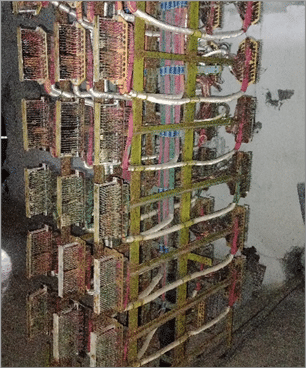

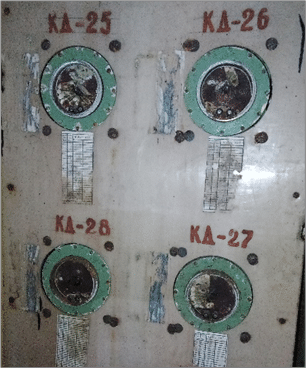

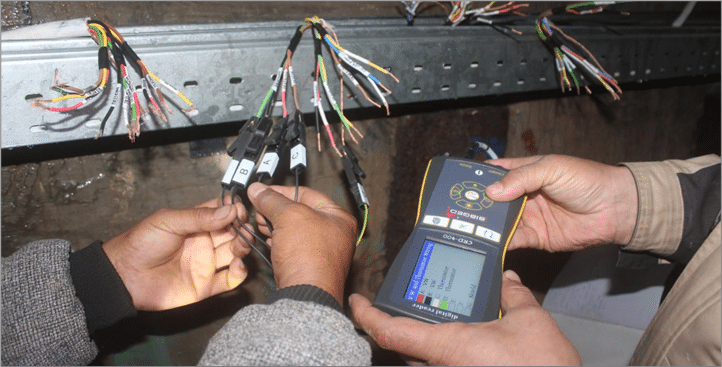

An initial assessment was conducted to verify the compatibility between existing electrical instruments (installed even 50 years ago) and today’s portable readout units and automatic data loggers.

During the inspection by the specialized technicians, the modern portable readout units were used to check whether the current technology is compatible with the old instruments installed.

Once confirmed, the legacy instruments were integrated with the new system, allowing automated readings and real-time data transmission, significantly improving monitoring accuracy and response time.

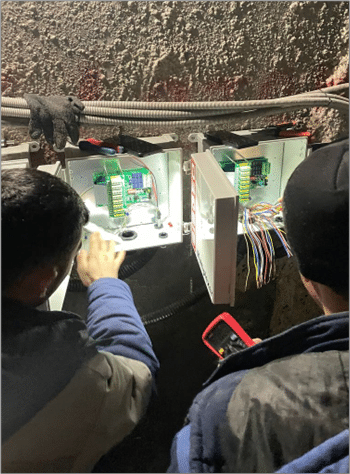

3 Automation of Existing Instrumentation

Modernizing a Dam Structural Health Monitoring (SHM) system begins with automating the existing sensors to enhance data accuracy and minimize manual labor. This process includes the integration of automated data loggers with the instruments already in place, such as vibrating wire strain gauges and thermometers that were installed during the construction of the dam. Ensuring access to these instruments is crucial.

Additionally, remote access is implemented to allow real-time visualization of the collected data. The data from the automated instruments is transmitted to a centralized data management platform, where predefined alarm thresholds are set. This setup enables immediate alerts in the event of abnormal conditions, allowing engineers to respond proactively and ensure the continued safety of the dam.

4 Installation of New Monitoring Equipment

In cases where existing sensors are insufficient, installing new monitoring instruments is necessary. The selection of sensors depends on dam type, geological conditions, and structural risks. Key instruments in this five dams are here following listed.

4.1 Open Standpipe Piezometers for measuring water table level

In Hisorak and Akhangaran dams, the existing stand pipe piezometers prior to rehailitation were read manually with a water level indicator. Many piezometers have been automated with relative pressure transducers [1], which do not require barometric compensation, and wireless logger nodes [2].

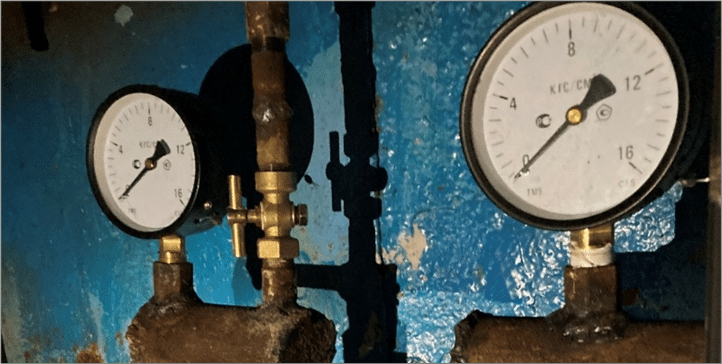

4.2 Uplift piezometers in dam foundations

The existing up-lift piezometers that existed before the rehabilitation in the Hysorak, Andjan, Charvak and Tupalang dams were read manually through a manometer. In many case the manometer was not readable or not working. A vibrating wire pressure transducer had already been connected to some piezometers, but all these devices, due to their low quality, did not function after only a year from installation. The renovation of these instruments consisted in replacing the connecting pipes by inserting closing/opening valves, and connecting as shown in the photo below a new manometer, new vibrating wire pressure transducer [3] and a vacuum valve to prevent the transducers from breaking during sudden pressure changes, such as during a reservoir draining. A QR-Code label is attached to the cable of the vibrating wire pressure transducer, giving access to all information about the gauge, e.g. serial number, calibration date and calibration parameters.

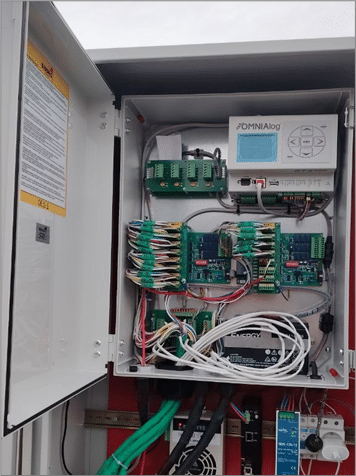

Vibrating wire pressure transducers was automated through wired connection to OMNIAlog datalogger [4].

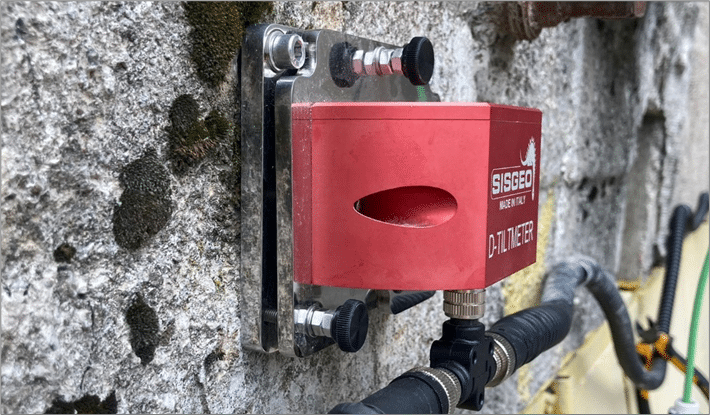

4.3 Tiltmeters for detecting structural deformations

In Andijan dam, hydraulic settlement systems have been installed with a reference tank in the body of the dam and thus within the possible active settlement zone. A system made in this way is not able to measure structural vertical displacement correctly: if, for example, the dam body were to move rigidly vertically, this system would not measure any failure.

In order to be able to monitor the subsidence of the dam body correctly, very invasive, and expensive work would have to be carried out, for example by installing extensometers in the foundations. Together with the owner of the dams, it was therefore decided to install tiltmeters [5] to monitor any rotation at strategic points in the foundations and the dam body.

4.4 Jointmeter for monitoring cracks and joint movements

To measure the movement of structural joints and cracks, there were mechanical references on the Andijan and Hisorak dams: measurements was taken manually with calipers.

To make this measurement more precise and automated, vibrating wire joint meters [6] in 3D configuration were installed on the dam body, capable of measuring movements in the three main directions.

4.5 V-notch for measuring the seepages

All 5 dams under rehabilitation have V-notches for leakage monitoring. Only a few V-notches were instrumented but did not give results because the sensors are not working correctly, and because they were completely cluttered with soil, mud, algae, and other materials. The main thing that has been done is to make the on-site staff aware of the scheduled cleaning of the V-notch pools.

Many V-notch pool was instrumented with new electrical transducer [7] in order to have the flow data on the web monitoring portal of the dam.

4.6 Telependulums for detecting horizontal movements of concrete dams and their foundations

The telependulums are intended to automatically read the direct pendulums and inverted pendulums. Direct pendulums are used to monitor the verticality of the dam, while inverted pendulums are used to monitor any horizontal displacement of the dam foundations.

The pendulums of the Andijan dam had already been instrumented, but only functioned for a few months.

The T-1000 telependulums [8] replaced the old, non-functioning device and, thanks to the connection to the OMNIAlog data logger, are now able to send measurements at defined regular intervals to the Owner’s web monitoring platform.

Measurements made with telependulums are verified redundantly with the manual measurements of the optical coordinometers already in use.

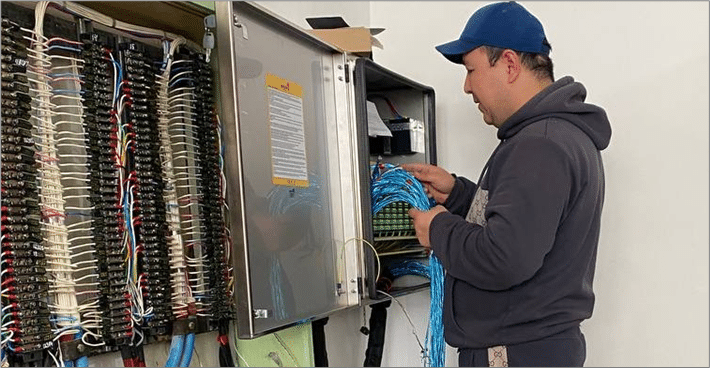

4.7 Wired automatic data acquisition system

The reliability and flexibility of the wired data logger is one of the key points for the success of a dam monitoring system. The system chosen for the rehabilitation of Hysorak, Andjan Charvak and Tupalang dams is the OMNIAlog system [9]. Depending on the requirements in the structures, the instrument cables were either connected to external multiplexer boards away from the logger box and then connected to the logger itself with a single cable, or the instruments were connected directly inside the acquisition system cabinet.

The data logger was then connected via a fibre-optic Ethernet to the local server to be able to have the data on the web portal

4.8 Wireless datalogging system

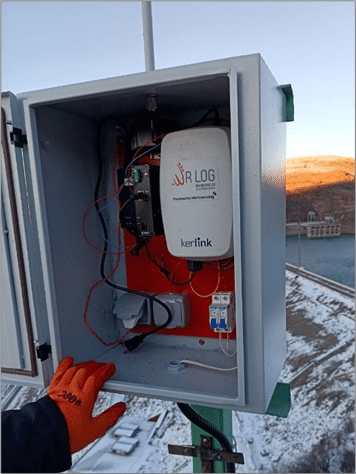

Wireless data acquisition systems are very practical in all those cases where laying cables is impossible or extremely costly. The wireless acquisition system chosen was the WR-Log system [10]. The system works in the following way:

- an instrument or small groups of instruments are connected via cable to a so-called battery-powered node

- the node transmits the collected data via radio (wireless) to a concentrator called gateway

- the gateway takes care of transmitting the data via router or Ethernet cable to an FTP or email

The wireless data acquisition system has been used in all dams, especially for automatic monitoring of hydraulic level data in standpipe piezometers. Gateway was connected through fiber optic only to the local server.

4.9 Meteorological station

Meteorological data are crucial for dam monitoring. In the Uzbek dams that are the subject of this work, these types of instruments were already present and functioning.

Meteorological stations for dams must measure at least the following parameters:

– amount of rainfall (rain or snow)

– air humidity

– air temperature

– wind speed and direction

– solar radiation

The meteorological data, cross-referenced with the sensor data described above, are crucial for monitoring the efficiency of the dam.

5 The strategic importance of selecting reliable partners

An essential aspect of structural health monitoring systems rehabilitation in existing dams is the careful selection of designers, suppliers and the technical installation and training team of resident technicians.

In this SHM rehabilitation experience of 5 dams, we found that many instruments installed more than 50 years ago were still working, while those installed 3 years ago stopped working a few months after installation. We tried to search for the previous instrumentation supplier, but nothing could be found on the web.

Given the complexity and critical role of SHM systems, partners must demonstrate a long history in the industry, with proven references and successful implementations in similar large-scale infrastructure projects. Choosing an established supplier ensures not only the reliability and durability of the equipment, but also access to specialised technical support, long-term maintenance services and compatibility with both traditional and modern data acquisition systems. Moreover, reputable suppliers are more likely to offer comprehensive training programmes for local personnel, facilitate integration with remote monitoring platforms and provide updates in step with technological advances.

6 What’s next?

Future advancements in IoT, AI-driven analytics, and digital twin technologies would be set to revolutionize dam monitoring, significantly enhancing resilience against structural risks. By combining real-time sensor data with intelligent algorithms and virtual replicas of physical assets, engineers would be able to monitor dam conditions continuously and predict potential issues before they became critical.

IoT devices embedded in the dam structure would collect data on pressure, temperature, displacements, inclination, seepage, and more. This data would be fed into AI models that would detect anomalies, recognize patterns, and generate early warnings. Simultaneously, digital twins—virtual models that mirror the physical dam in real time—would allow engineers to simulate scenarios, assess the impact of environmental changes, and optimize maintenance strategies.

The integration of these technologies would allow for proactive rather than reactive approaches, reducing the risk of structural failure and improving overall dam safety. Operators would be able to access dashboards with live updates, risk forecasts, and recommended actions, enabling faster and more informed decisions.

As these tools became more accessible and scalable, they would redefine how critical infrastructure is managed. From aging dams in need of modernization to newly built smart structures, this digital transformation would pave the way for a safer, more sustainable future in water resource management.

7 Conclusion

Rehabilitating and optimizing a dam’s monitoring system enhances safety, operational efficiency, and decision-making capabilities. By automating existing instruments and integrating modern SHM technologies, dam operators can transition to a proactive monitoring approach. Future advancements in IoT and AI-driven analytics will further revolutionize dam monitoring, ensuring higher resilience against structural risks.

References

- Sisgeo vented pressure transducer page, https://sisgeo.com/products/piezometers/vented-pressure-transducers

- Sisgeo WR-Log wireless dataloggers page, https://sisgeo.com/products/dataloggers/wr-log-wireless-dataloggers

- Sisgeo standpipe piezometers page, https://sisgeo.com/products/piezometers/casagrande-and-standpipe-piezometers

- Sisgeo vibrating wire piezometers page, https://sisgeo.com/products/piezometers/vibrating-wire-piezometers

- Sisgeo digital tiltmeters page, https://sisgeo.com/products/tiltmeters/360-digital-mems-tiltmeter

- Sisgeo electrical jointmeters page, https://sisgeo.com/products/crackmeters-and-joint-meters/electrical-crackmeters-and-jointmeters

- Sisgeo V-Notch page, https://sisgeo.com/products/piezometers/v-notch-and-flow-meters

- Sisgeo T-1000 telependulum page, https://sisgeo.com/products/pendulums/t-1000-telependulum

- Sisgeo OMNIAlog page, https://sisgeo.com/products/dataloggers/omnialog-datalogger

- Sisgeo WR-Log page, https://sisgeo.com/products/dataloggers/wr-log-wireless-dataloggers