The BC Ministry of Transportation and Infrastructure (MOTI) is widening Highway 1, the Trans-Canada Highway, by adding an additional lane in each direction in the areas east of Vancouver. Each section of highway presents new challenges for the construction work, and separate contractors are hired to complete each portion of the project.

Instratus Monitoring Ltd. (Instratus) was hired by the general contractor selected to construct a section of highway that was located in an historic flood plain. The underlying soils are compressible and require significant surcharge loading to consolidate. As part of the construction in this section a number of geotechnical instruments were required to monitor the ground reaction as the surcharge fills were placed. Instratus utilised Sisgeo instruments to accomplish this.

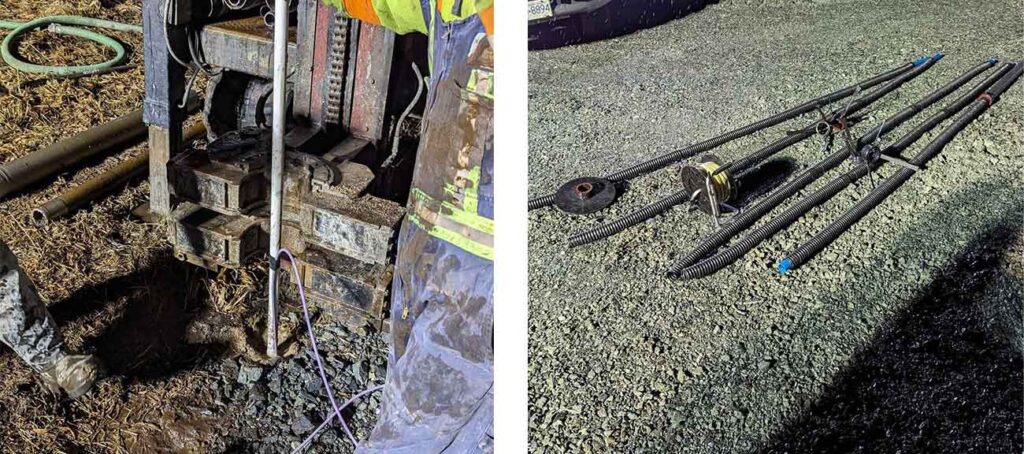

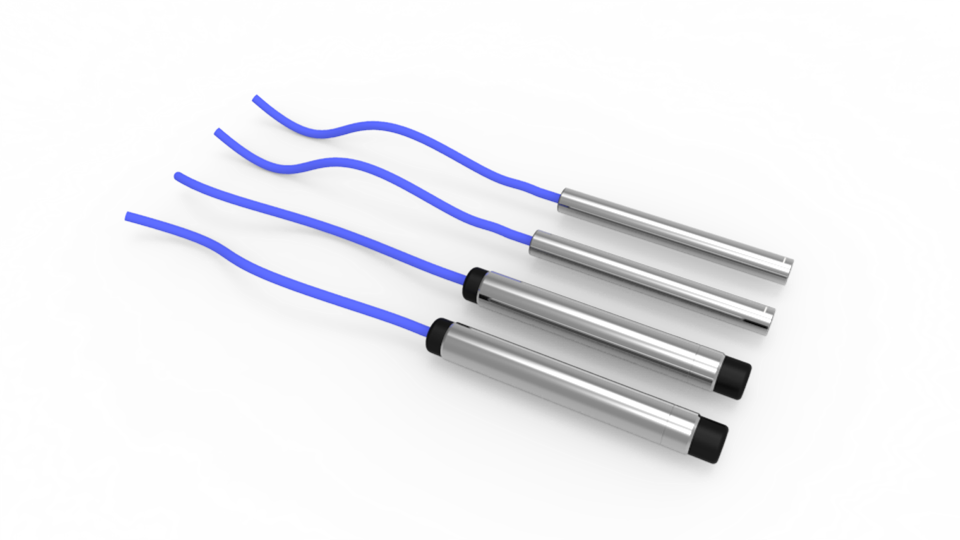

The project called for multiple vibrating wire piezometers installed across the project to monitor pore water pressure changes as the surcharge loads were applied. Instratus used Sisgeo Heavy Duty PK45S vibrating wire piezometers with armoured cabling for this project. Due to the large expected settlements (> 1.5 m) and the installation methods heavy duty equipment was required to minimize the potential for damage. The piezometers were installed at depth within a 1.2 m sand pack. The excess cable was trenched to the side of the fill area so that construction filling could continue without the need to extend the cabling vertically. The devices were connected to dataloggers to collect hourly readings throughout construction.

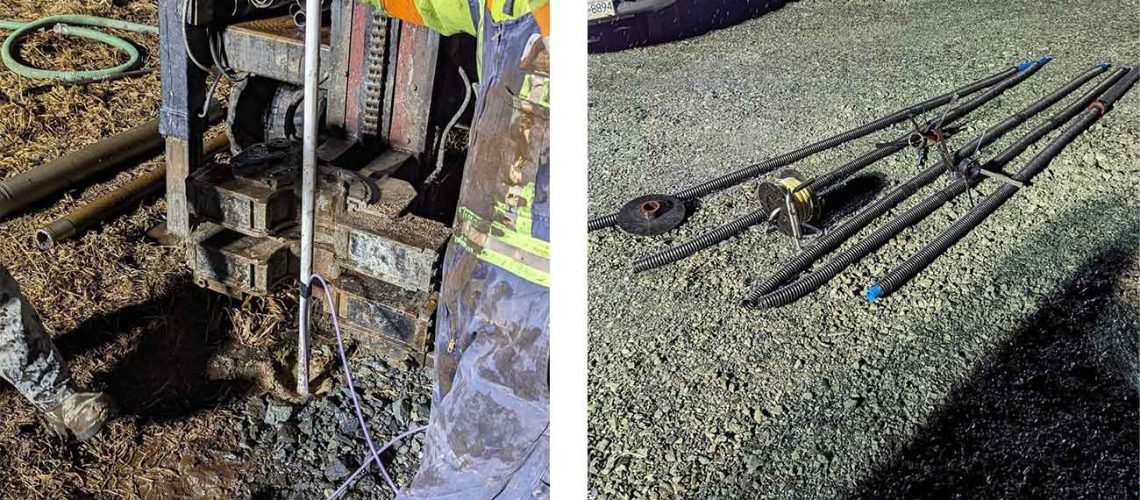

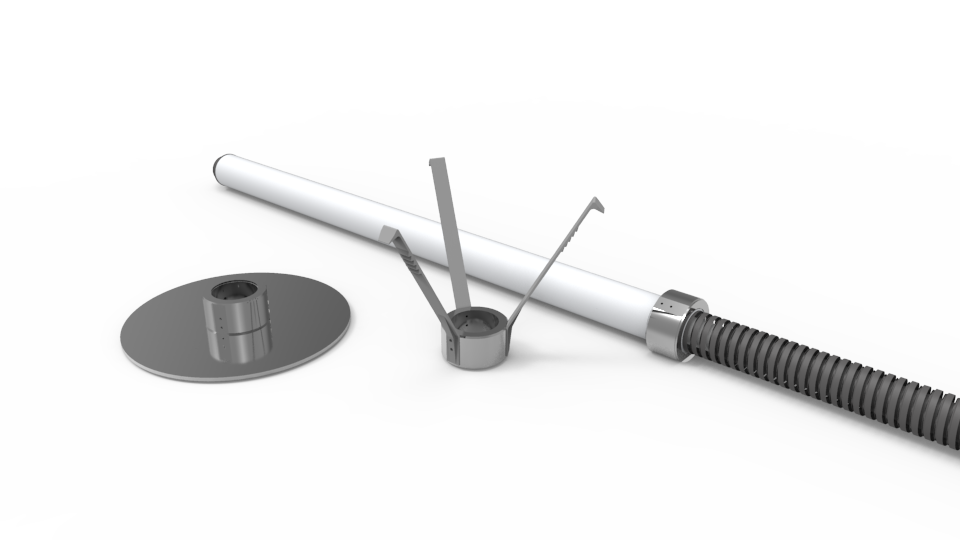

In addition to the piezometers, the owner’s engineer wished to monitor the consolidation of the underlying soils throughout construction. This was accomplished by using a Sisgeo magnetic settlement system. The magnetic settlement system uses a rigid PVC access pipe installed within a flexible corrugated pipe to which magnetic targets are attached at the selected depths. The system is installed within a borehole and grouted in place. As settlement occurs, the magnets which are coupled with the soil strata, move vertically with the corrugated pipe compressing. A reed switch probe is used within the rigid access pipe to measure the depth to each magnetic target.

SISGEO’s magnetic settlement system was easy to installed due to its unique design. The access pipe is provided in 3m sections with threaded ends making them easy to lower down the borehole and join together. The corrugated sleeve that surrounds the access pipe is provided in a long roll with specific „cut-points“ at 1 m intervals. At each cut point, the sleeve can be cut with a utility knife and then threaded into itself. This allows the corrugated pipe to be added in sections down the borehole without the need for couplers. This is the same for when the access pipe and sleeve is extended as additional fill is placed. This design also allowed Instratus to prepare each 3 m section with magnetic targets installed at the correct depths as drilling occurred, making for a quick and easy install.

A special thanks to Dion Lauriente Principal at Instratus Monitoring Ltd. Instratus Monitoring Ltd. website: https://www.instratus.ca/