The Madrid M30 motorway, the inner ring road of the city, is at the centre of a major urban renewal project. At the current time the M30 is a ‘barrier’ to movement in the urban areas it runs through. Despite its necessity as part of the road infrastructure of Madrid it causes much pollution to the air and also the Manzanares River which it runs close to.

The new sections of road construction will total 99km, 56km of which will be in tunnels.

Construction started in September 2004. The total project budget is estimated at €3.7 billion.

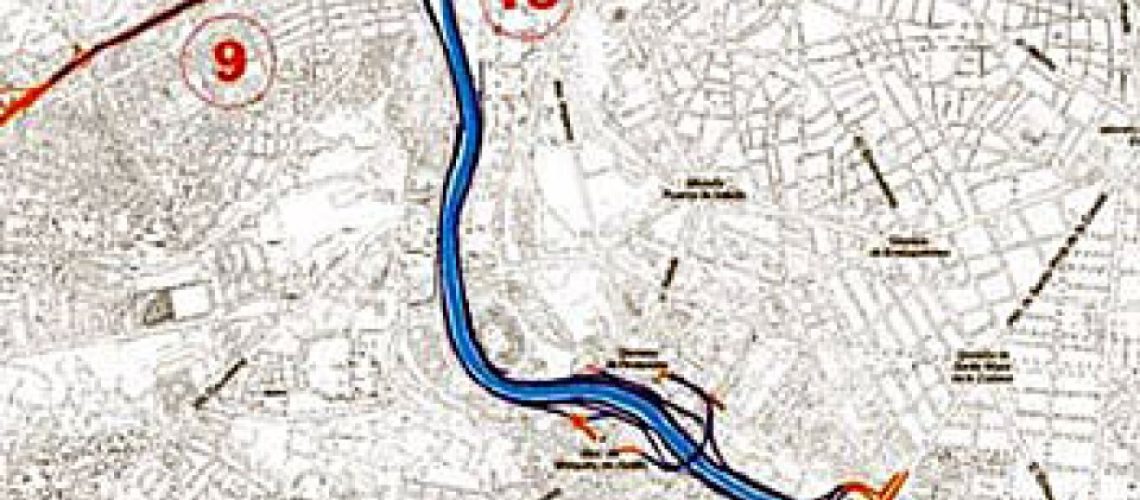

The motorway reconstruction is to take place in sections and has been divided into 15 separate projects and four regions – north, south, east and west.

Municipal agency Madrid Calle 30 has awarded Necso and Ferrovial Agroman the construction contract for the north tunnel on the south bypass for €340 million. The south tunnel on the south bypass will be constructed by a joint venture between FCC and ACS Dragados for €429 million. The south bypass is an 8,344m, three-lane infrastructure divided into two tunnels, of which 7,212 m is to be built by 15m-diameter TBMs and 632m by cut-and-cover tunnel method. Sinking of the shafts for the TBMs started in August 2004 and construction will last 30 months. Both tunnels, one in each direction, will allow drivers to avoid the A-4 intersection.

In September 2004 MHI-Duro Felguera SA, a joint venture between Mitsubishi Heavy Industries Ltd (MHI) and Duro Felguera SA, received an order to supply the world’s largest Earth Pressure Balanced (EPB) Tunnel Boring Machine (TBM), with a diameter of 15m (4,000t, 160m long) and an advance rate of 0.665m/min, to Dragados-FCC UTE of Spain. Design work on the equipment is to be performed by MHI and manufacturing will be carried out by Felguera Construcciones Mecánicas SA. The machine fabrication is scheduled to be completed in July 2005.