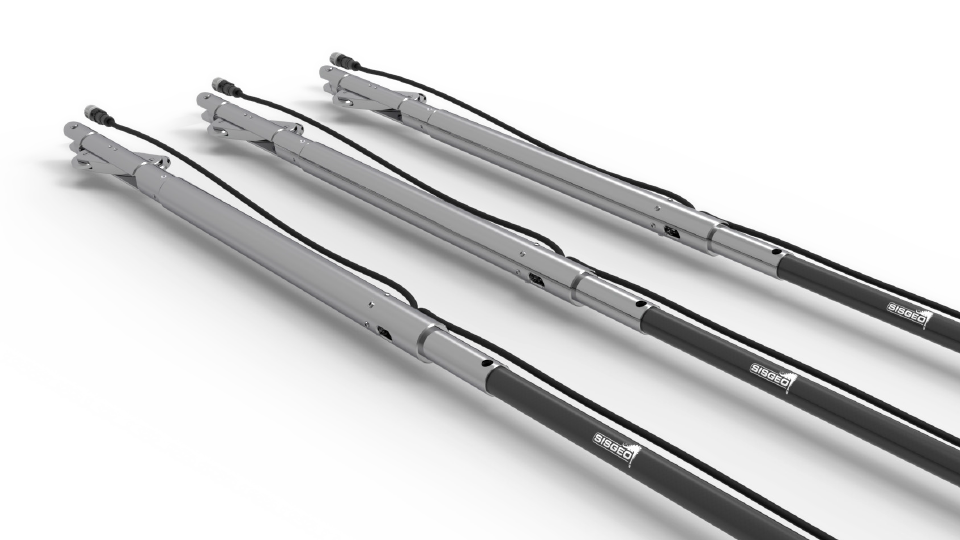

Horizontal In Place Inclinometers

Codes der Referenzprodukte: S441 MEMS Horizontal IPI gauge consists of a stainless steel assembly and carbon fibre extension rod. IPI string is composed by a chain of IPI gauges with carbon fiber extension rods and a terminal wheels assembly. A string of horizontal IPIs is usually installed inside inclinometer casing buried within trenches, foundations or […]

FAQ#116 – How do I configure a WR-Log digital node to read RS485 Sisgeo TIMED sensors?

Sisgeo digital instruments can operate in two powering modes: TIMED or ALWAYS-ON (for more information see F.A.Q.#094).A string of mixed instruments consisting of TIMED gauges and ALWAYS-ON gauges cannot work.The first thing to do is therefore to check that ALL connected instruments in your array are set to TIMED mode.You can check the powering mode […]

FAQ#095 – How long does a chain of digital sensors take to be read?

It mainly depends from the powering mode of the gauges (refer to FAQ#094 for the description of the powering modes). AN EXAMPLE WILL BETTER CLARIFY THE ANSWER. In a batch of 240 gauges, unless otherwise requested by the Customer, the addresses are settled from #001 up to #240. In a borehole is installed a chain of 30 […]

FAQ#087 – Could the IPI, BH Profile and DEX probes have problems in frozen water?

Sisgeo suggest that frozen water within the inclinometer casings is to be avoided due to following reasons: – Ice within the casing will affect functionality of the systems by blocking the individual probes;– Mechanical damages can occur to the probes, but also to the inclinometer casing due to the expansion of frozen water In any […]

FAQ#076 – Why it is necessary add a termination resistor to the last digitized sensor of each RS-485 chain?

All SISGEO digitized instruments (IPIs, Tiltmeters, H-Level…) use the RS-485 serial communication protocol The RS485 protocol contemplate a termination resistor. The recommended chain connection is point-to-point (multidropped) nodes as a bus mode (line). Star, ring or multiply network connection are not recommended. SISGEO dataloggers has already a termination resistor assembled (typically 120Ω). On the opposite […]

FAQ#075 – What parameters are saved in SISGEO digital sensors? What information must the Customer provide when ordering?

All SISGEO digital sensors (e.g. IPI, BH Profile, MD Profile, LT Inclibus, Tilt-meter, RDS, H-Level, etc.) use the Modbus communication protocol over RS-485 serial. SISGEO digital sensors are connected to each other with a single signal cable. The parameters that are configured at the factory for each digital sensor are as follows: Upon confirmation of […]

FAQ#074 – Which kind of datalogger is necessary to read a SISGEO digital sensors?

The sensors are read connecting the end cable to a Modbus Master unit (i.e. OMNIAlog or miniOMNIAlog) with RS-485 interface (DCE, Half duplex, no Echo) able to manage communication with SISGEO Modbus RTU communication protocol. SISGEO’s communication protocol is available for the release upon request. The power [W] of power supply must be chosen according […]

FAQ#073 – Which is the maximum number of digitized sensors (RS-485, Modbus), the maximum number of chains and the maximum length of cable in a RS-485 network?

Last update: October 2021 All the SISGEO digitized sensors utilize a RS485 interface with Modbus protocol. 1.The maximum number of digitized sensors in a RS-485 network are 247 (theoretical) 2.The maximum number of digitized sensors chains that is possible to connect to Modbus master unit (as OMNIAlog or miniOMNIAlog) are 4. 3. About the maximum […]