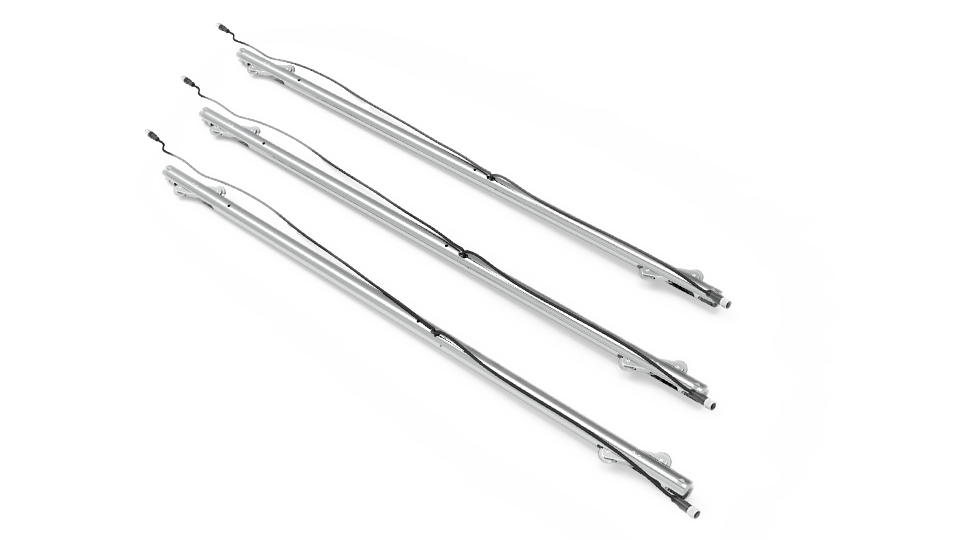

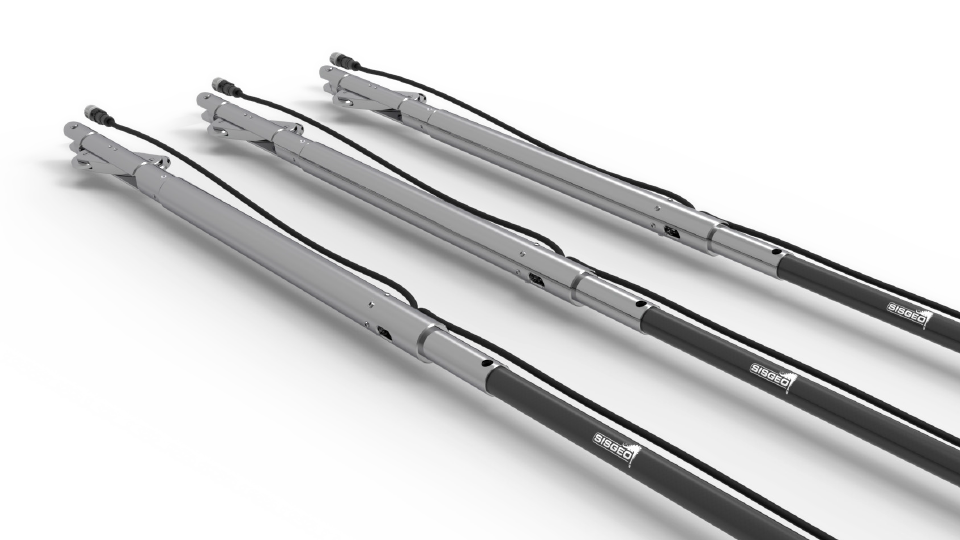

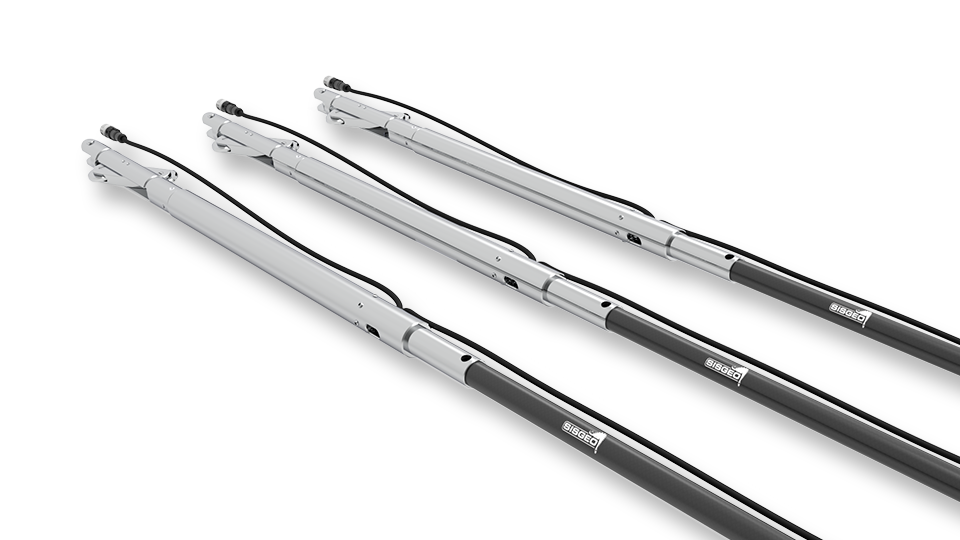

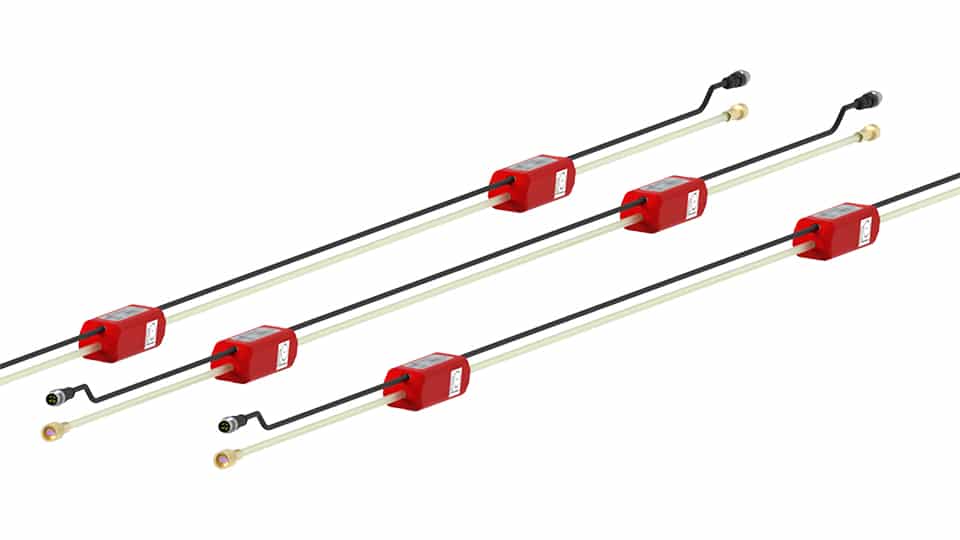

360° LT-Inclibus array

Codes der Referenzprodukte: LTIB

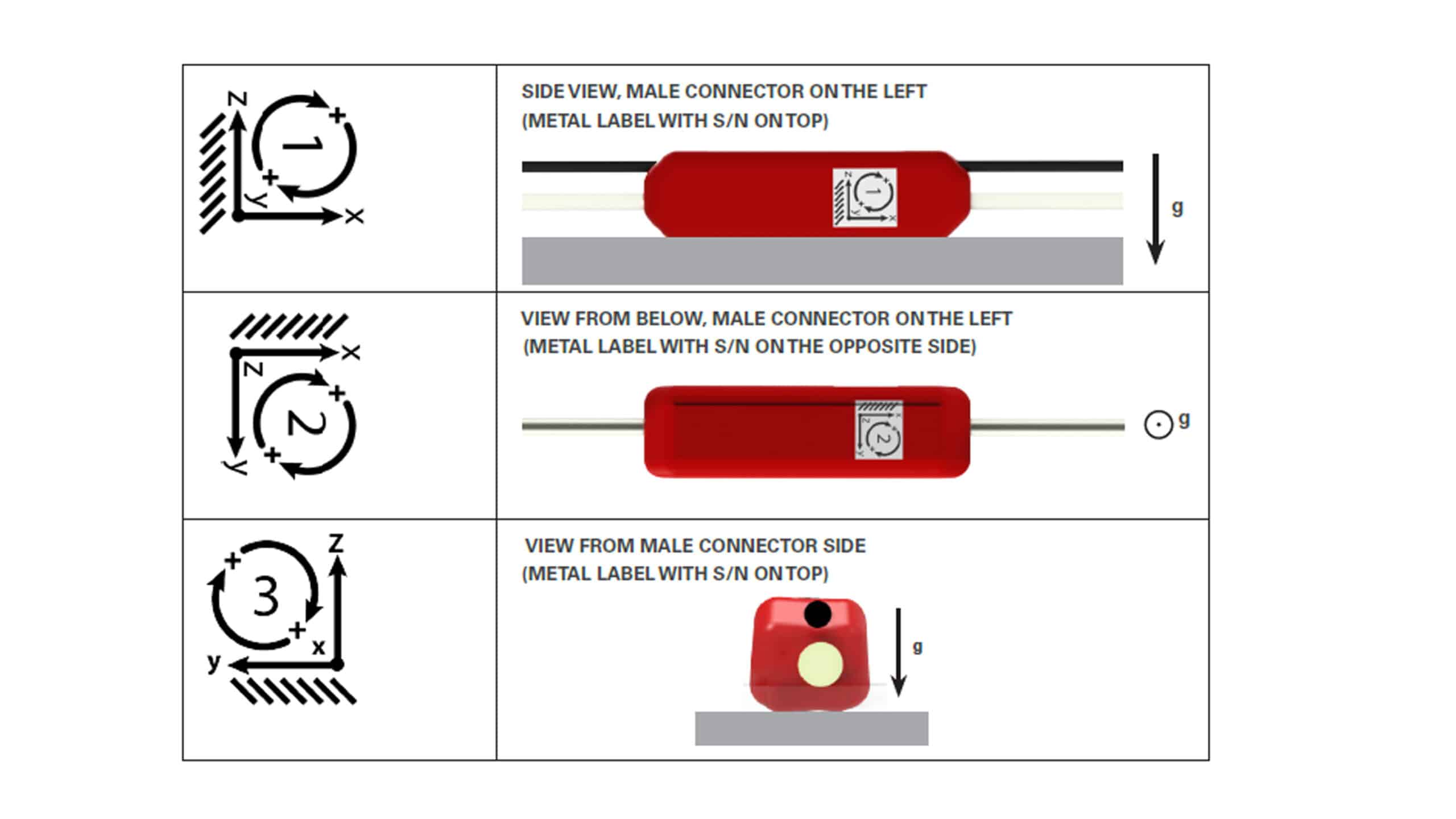

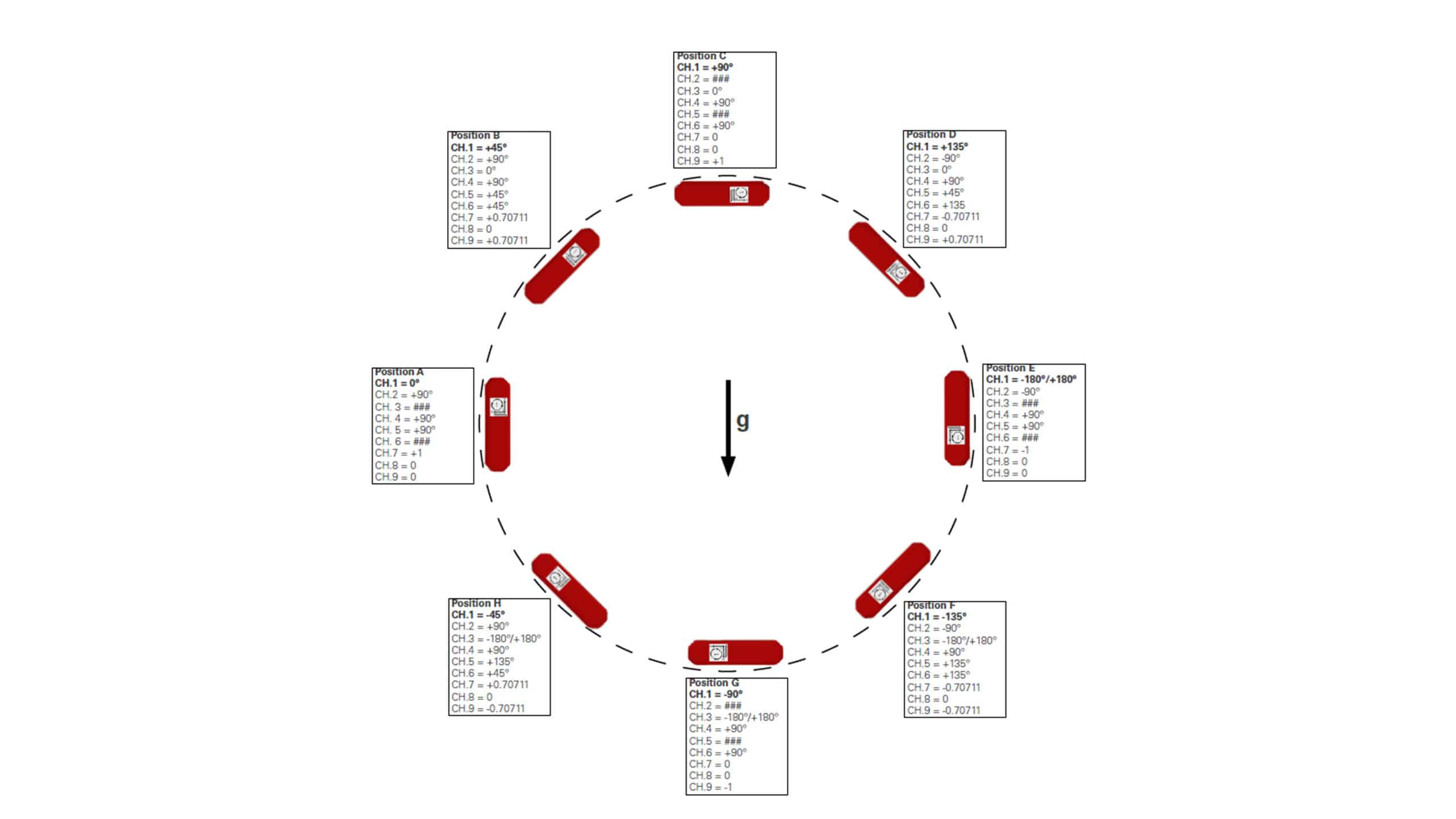

Tiltmeters are instruments that measure angles respect to the gravity acceleration vector. To get this result an accelerometer is required. It measures the projection of acceleration gravity on its sensing axis. Sensor can have 1, 2 or even 3 sensing axes.

The MEMS (Micro Electro Mechanical Systems) implementation of accelerometers it’s pretty young (about 20years) but mature enough to have its strong reliability been proven. MEMS are indeed silicon chips machined to create a mechanical part inside. The required electronic to read out the signal is inside the same chip.

The working principle is a spring-mass system: a mass (rotor) is anchored with springs to a fix frame (stator). When an acceleration occurs, the rotor moves respect to the stator loading or unloading the springs. That’s it: the displacement measurement is proportional to the applied acceleration. Displacement is measured with different technologies inside the chip but in its simplest form is related to a capacitance measure.

Sisgeo uses the state-of-the-art of MEMS accelerometers that implement several methods to compensate temperature variation and reduce the cross-axis error reaching very high accuracy.

Messen Mit

Fragen

zu diesem

produkt?

zu diesem

produkt?

Datenblatt

Handbuch

Modbus

Faq

Fragen

zu diesem

produkt?

zu diesem

produkt?

Datenblatt

Handbuch

Modbus

Faq