WHAT IS DAM REHABILITATION? Which is the role of a good monitoring system?

Dam rehabilitation is the process of repairing, upgrading, or modifying dams to improve their safety and functionality. Initially, this involves assessing the dam’s structural integrity and identifying any weaknesses that could pose risks. Next, engineers take steps to strengthen the foundation, repair cracks, and, importantly, improve spillways to handle extreme water flows. Additionally, modern monitoring systems are needed to detect issues early. Ultimately, dam rehabilitation not only extends the lifespan of the dam but also protects downstream communities and ensures a reliable water supply for irrigation, drinking water, and hydroelectric power generation.

The monitoring systems for dam rehabilitation involves upgrading or restoring monitoring equipment and technologies to improve the safety, reliability, and performance of the dam. Dams are critical infrastructures designed to manage water resources and produce electricity, many of which have reached the end of their useful life or may require extensive rehabilitation.

A good geotechnical and structural monitoring system plays a crucial role in dam rehabilitation by providing real-time data on the dam’s structural health and performance. It allows engineers to identify early signs of damage or instability, such as changes in seepage, pressure, or deformation. This information is vital for making informed decisions about repairs, upgrades, or preventative measures. Moreover, an advanced monitoring system ensures that the rehabilitation process is based on accurate data, helping to prioritize interventions, optimize maintenance schedules, and enhance the long-term safety and functionality of the dam. Without an effective monitoring system, rehabilitation efforts may lack precision, potentially compromising the dam’s integrity and safety.

In 2021, UNU-INWEH (United Nations University – Institute for Water, Environment and Health) published a report titled “Ageing water infrastructure: An emerging global risk.” The authors urged that by 2050, most of the earth’s population will live downstream of tens of thousands of large dams built during the 20th century, many of which have remained in operation beyond their useful life.

Our EXPERTISE FOR DAM REHABILITATION

Dam rehabilitation aims to ensure safety and operational performance, and the geotechnical and structural monitoring systems are essential for controlling, maintaining, and safeguarding structural integrity. Furthermore, the design, verification, installation, implementation, and maintenance of monitoring systems typically require extensive collaboration among professional engineers from various disciplines.

Realizing maximum benefits and the return on investment in monitoring instrumentation systems strongly depends on the efficiency of the data management platform. This platform transforms data into valuable analytics based on which authorities can make timely and informed decisions.

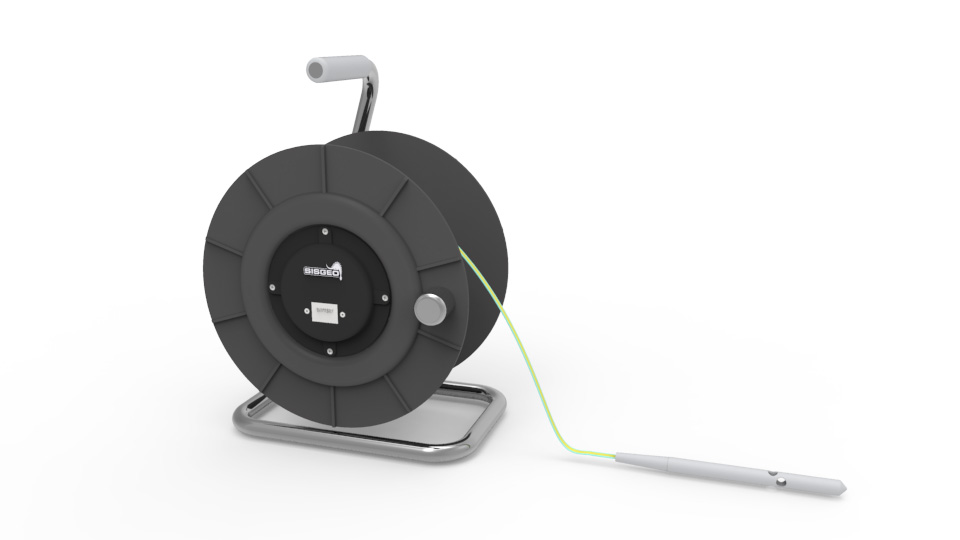

Sisgeo with Huggenberger and Sisgeo Latinoamerica, is honored to collaborate with hundreds of professionals in various disciplines. Over the past three decades, it has delivered state-of-the-art instrumentation solutions to over a Thousand dams worldwide. Sisgeo instrumentation solutions ensure high quality and provide dependable precision, usability, and, most importantly, unparalleled technical support.

In June 2025, Sisgeo became part of the Eddyfi Technologies family, joining Senceive and Sensor Networks, within the Remote Monitoring Solutions (RMS) product line. This means a significant expansion of the range of structural and advanced wireless connectivity solutions available to our customers.

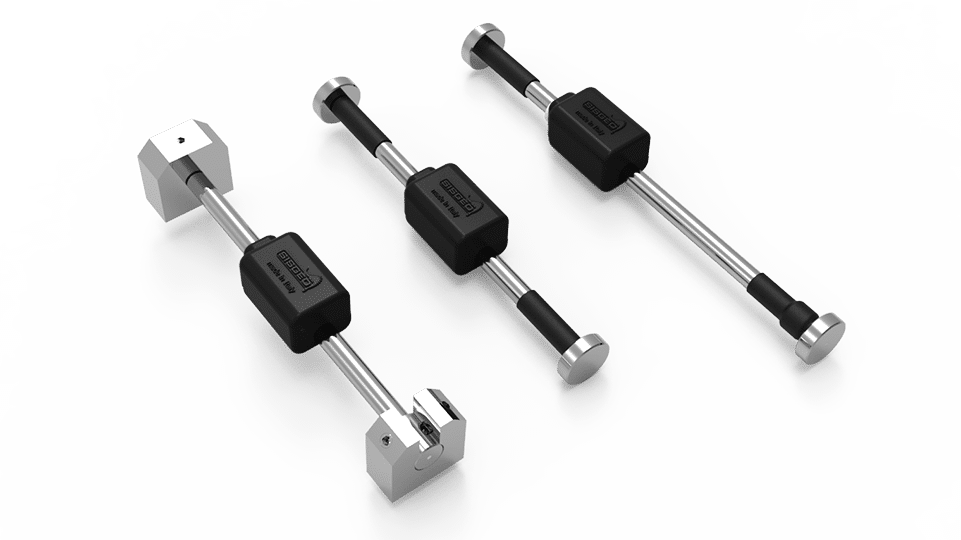

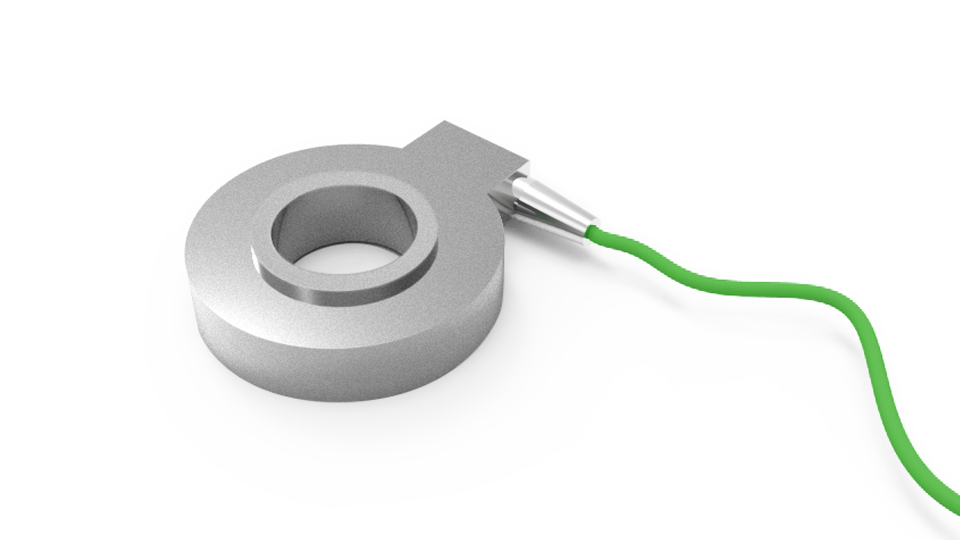

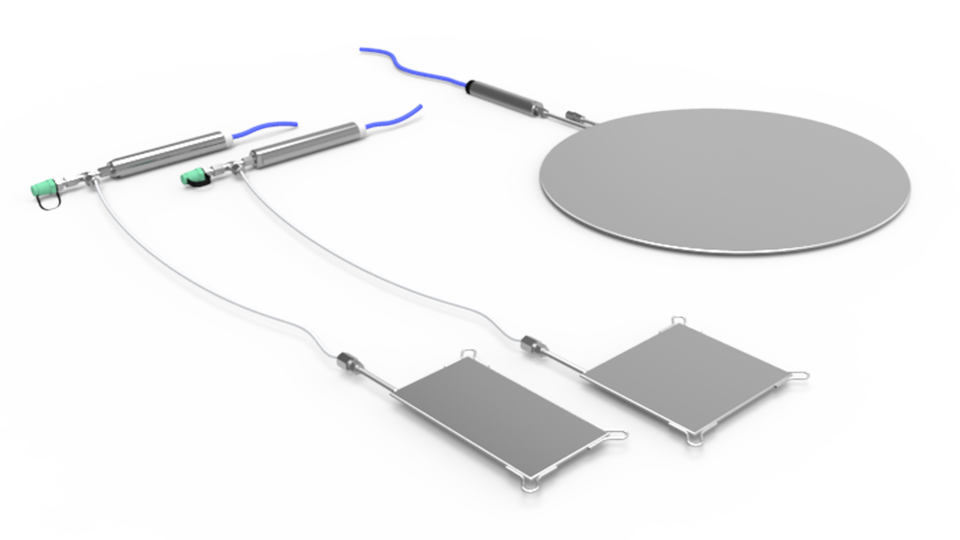

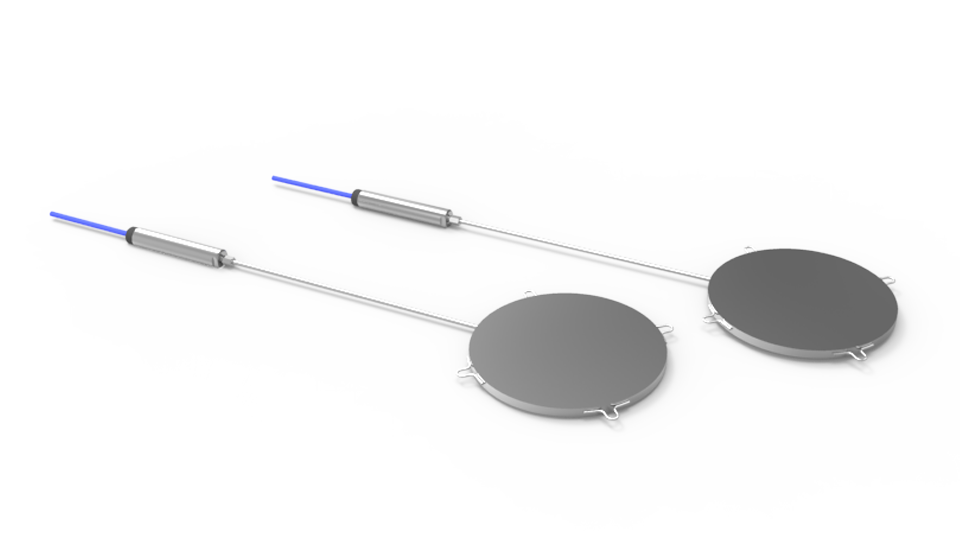

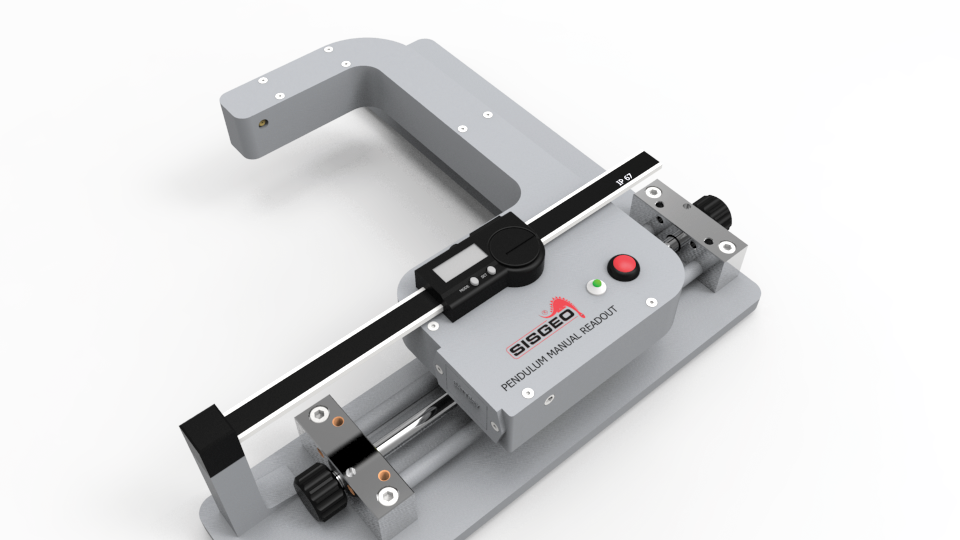

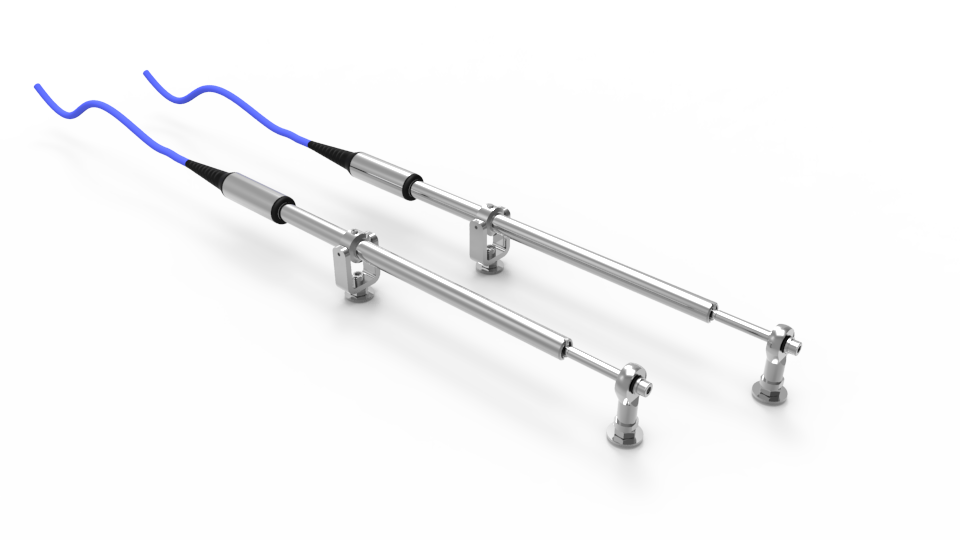

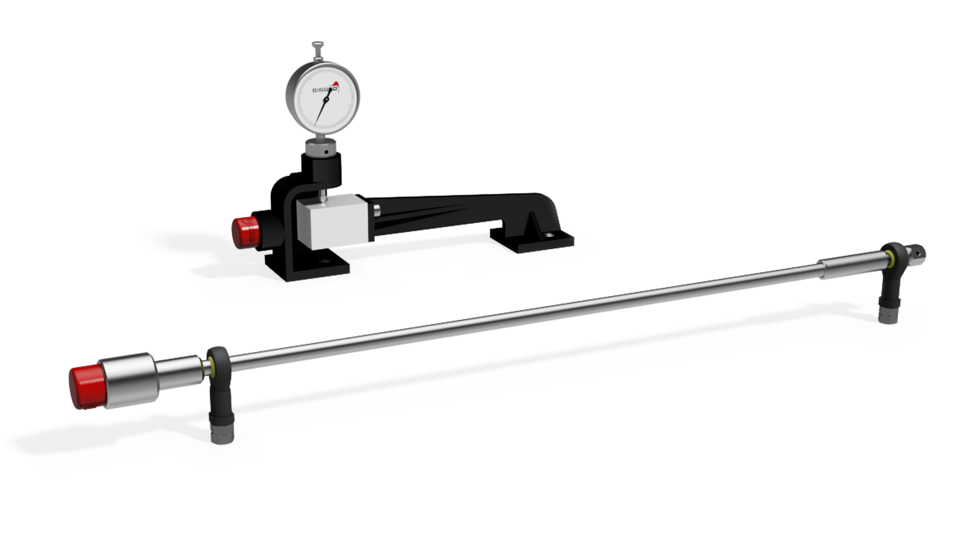

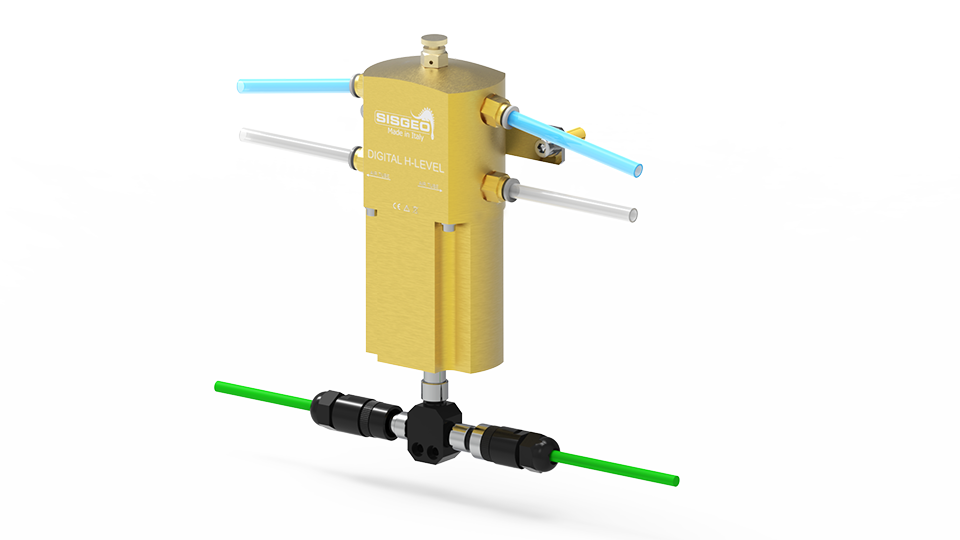

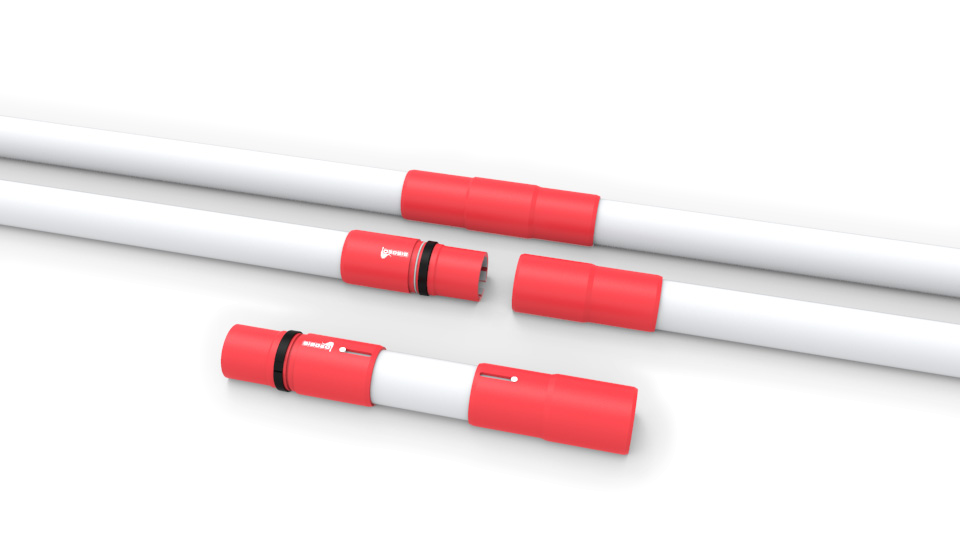

SISGEO, SISGEO LATINOAMERICA and HUGGENBERGER AG, offer full spectrum of specialized instrumentation solutions worldwide for dam rehabilitation, including:

→ Diagnosis and functional tests on existing instrumentation

The inspection of instrumentation functionality and monitoring processes such as data collection, data storage, and telecommunication systems is essential for dam rehabilitation projects, implying the following actions:

- Retrieving the existing technical documentation;

- Identification of out-of-use instruments;

- Organizing historical readings and highlighting anomalies;

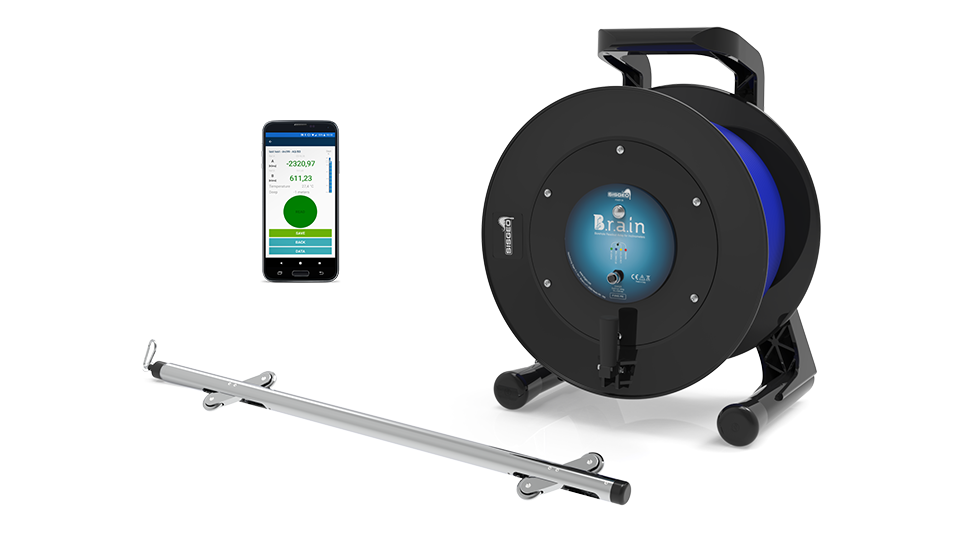

- Gathering new readings utilizing modern data loggers with data analysis capabilities;

- Evaluating the integrity of signal cables, electrical connections, and mechanical fixtures;

- Evaluating conversion formulas and regression models;

- Providing status reports and summarizing the findings;

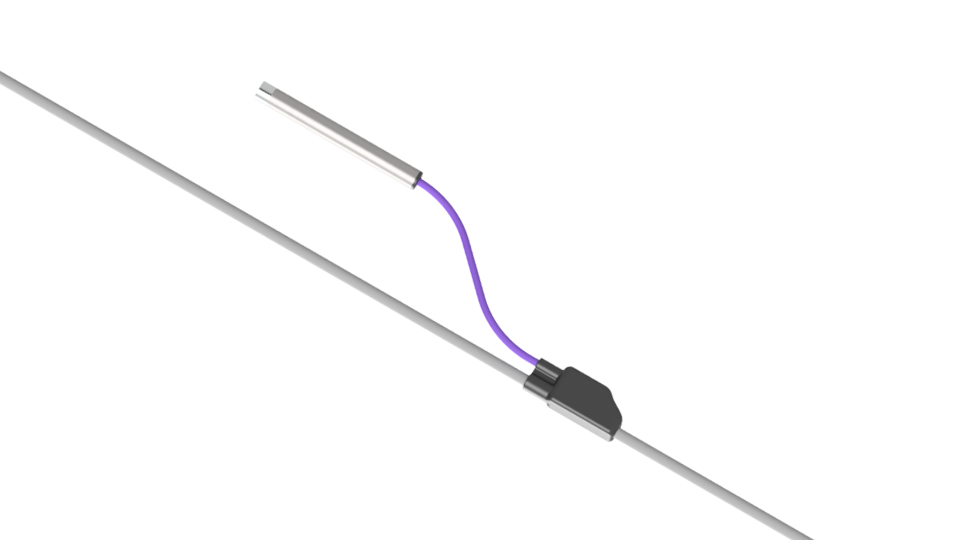

→ Data acquisition, digitization, and online accessibility

Given the site specificity and the client’s needs, the existing infrastructure can often be upgraded to a fully automated platform. The automation of monitoring systems is necessary for a variety of reasons:

- To avoid or mitigate human error in the data collection process;

- To set and reset the sampling frequency and enhance statistical inference as necessary;

- To digitize and compress the data, which significantly enhances data transmission and the storage capacity for historical records and, more importantly, facilitates access to the records;

- To minimize the sunk costs due to the reduced cabling and complexity of the central data acquisition system;

- To allow real-time dynamic and static asset monitoring without human intervention.

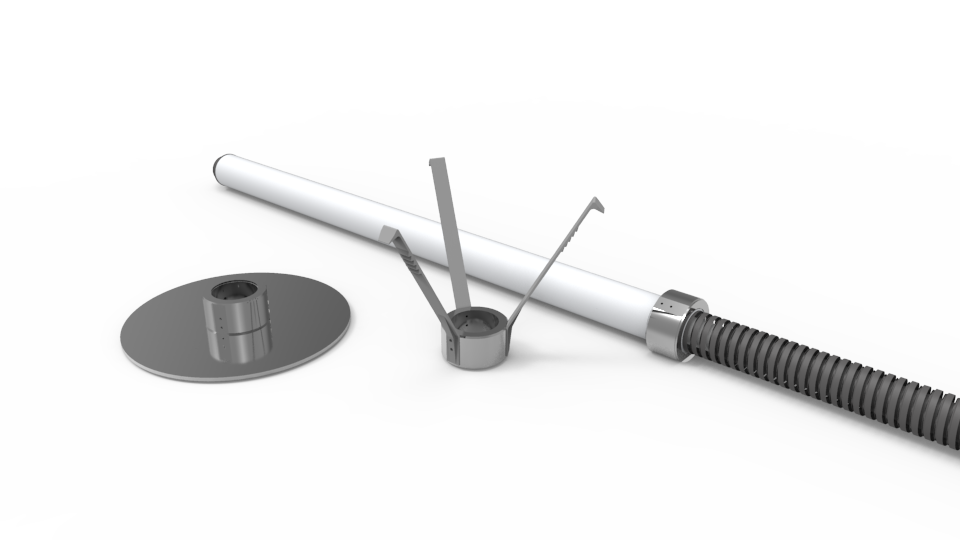

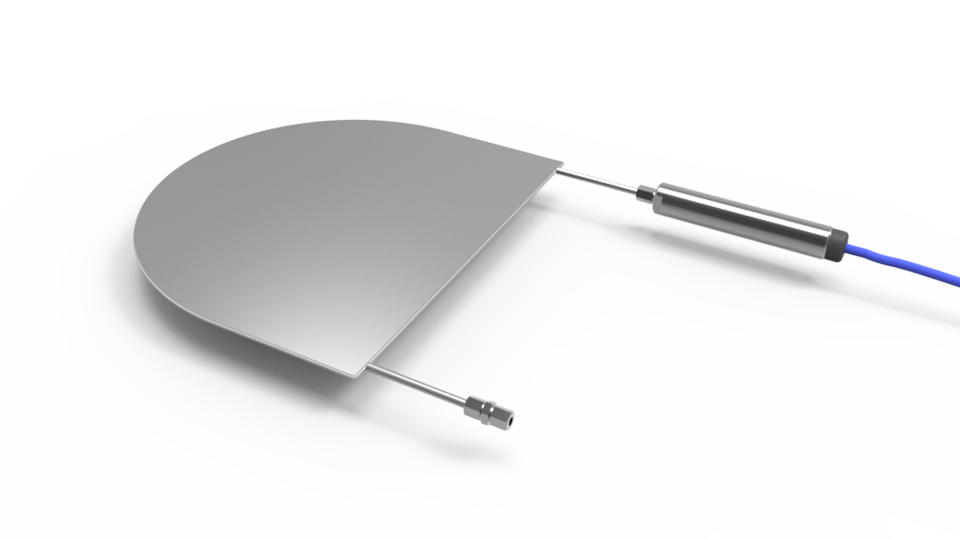

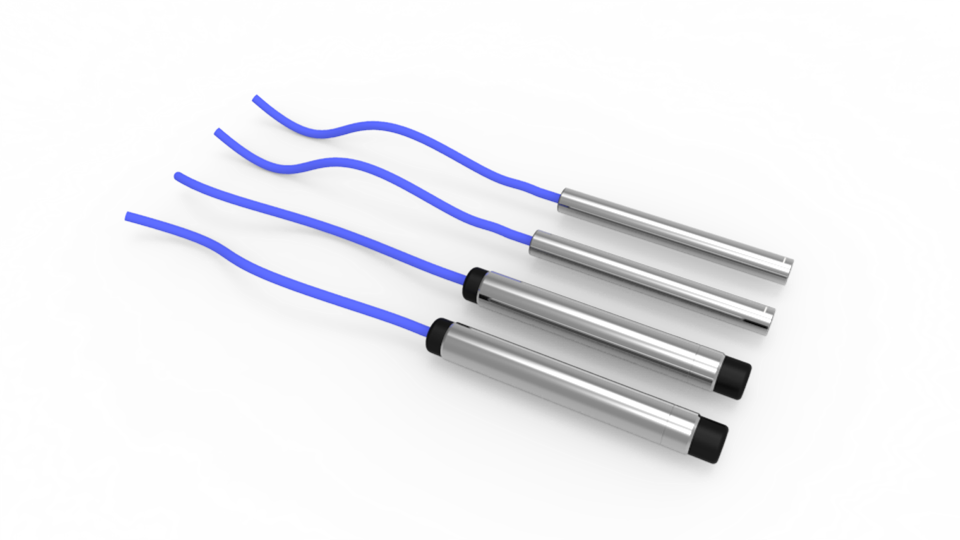

→ Design, supply and installation

Designing and implementing instrumentation and monitoring systems in engineering projects is vital for managing physical, engineering, and geological phenomena. Careful consideration of measurement needs, parameters, and instrumentation architecture is necessary. Critical parameters such as measurement range, frequency, accuracy, and data usage must be assessed. Design involves technical documents, plans, and maintenance schedules. Protecting instrumentation during civil works is crucial.

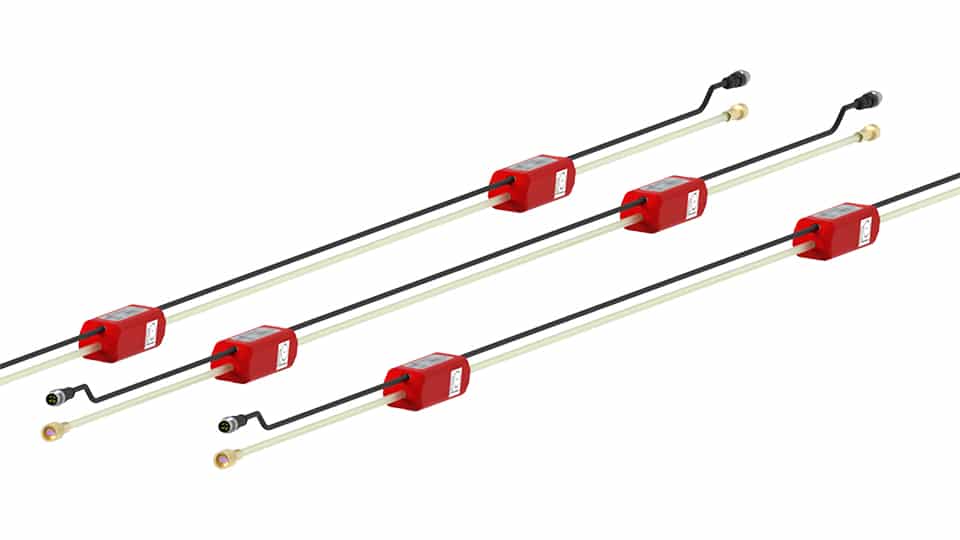

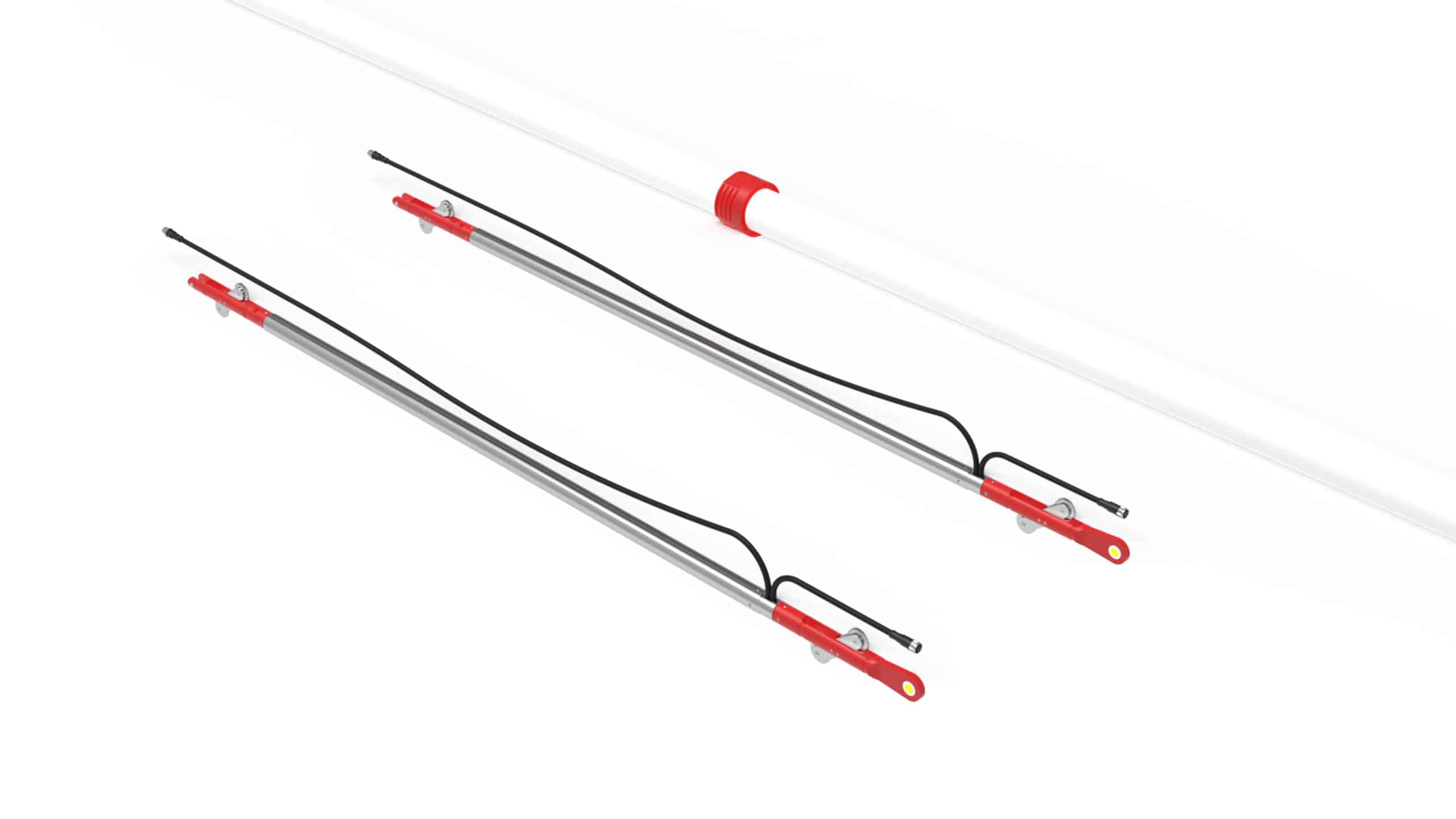

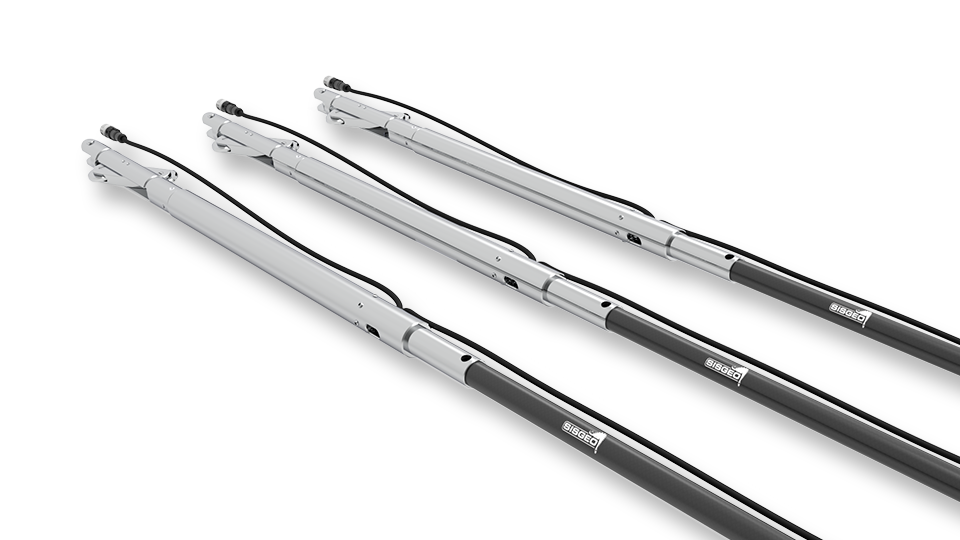

Sisgeo, a leading inclinometer technology provider, emphasizes detailed specifications and user manuals for efficient storage and installation. The installation phase requires strict adherence to specifications.

Sisgeo trains its staff for efficient installation, recognizing its impact on system performance. Meticulous design, detailed specifications, and expert installation are essential for high-quality monitoring solutions in engineering applications.

→ System maintenance operations

System maintenance operations include two main types:

A) Routine maintenance involves all system control and overhaul activities, including functional checks of all instruments and data loggers, inspection of remote connections and data transmission networks, and repair or replacement of sensors or components exhibiting abnormal

behaviour.

B) Extraordinary maintenance is typically initiated at the customer’s request to address repairs, faults, and malfunctions.

The frequency of maintenance plans primarily depends on the type of plant, environmental

conditions, and other specific factors. Generally, routine maintenance programs are conducted

more frequently (monthly) during the initial months, transitioning to quarterly or semiannual

schedules based on the customer’s resources and the availability of on-site specialists.

→ After-sales assistance, periodic calibration, repair and maintenance

Following installing the instruments and data loggers, our commitment extends to comprehensive technical support. Our dedicated support team is available to address any questions or technical issues that may arise. Whether you require assistance with product setup, configuration, troubleshooting, or periodic calibration services, our experts offer prompt and effective solutions to help you optimize your instruments’ functionality.

Additionally, our maintenance services encompass thorough inspections, testing, firmware updates, and any necessary adjustments to ensure your tools operate efficiently.