Pressure cells

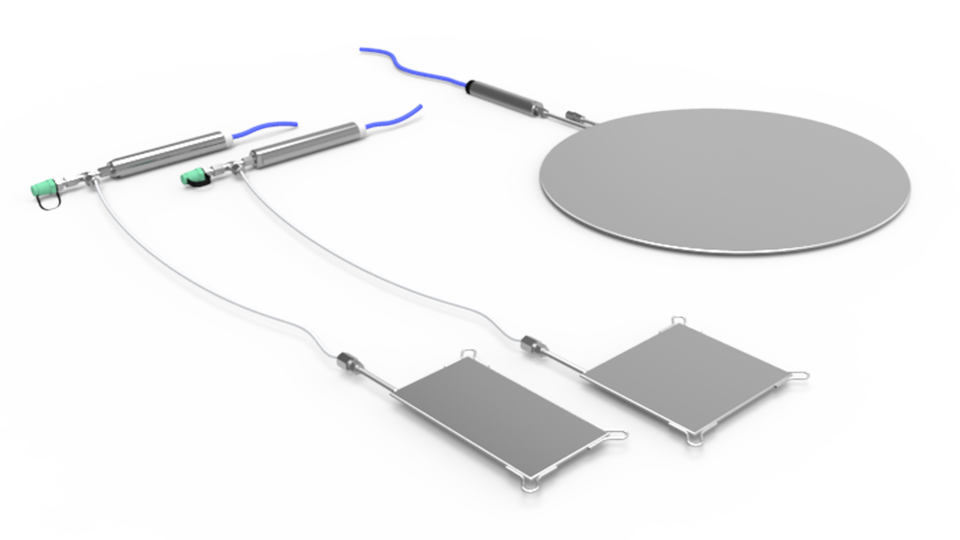

Pressure cells essentially consist of a pressure pad filled with deaerated oil, connected to a pressure transducer with a hydraulic tube. The size and shape of the pressure pad must be chosen according to the application, the expected pressure, the size of the structure in which it will be installed and the method of installation.

Pressure cells are commonly utilized during tunnel excavations and embankment dams’ construction.

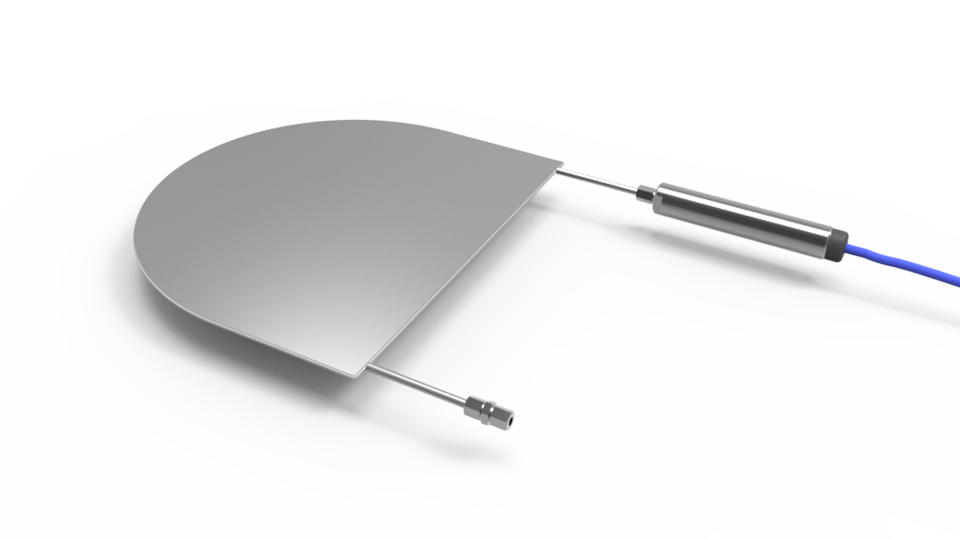

A flat jack is a device used to measure the stress or load-bearing capacity of a structure. It consists of a flat pad that is inserted into a thin cut in a concrete or rock structure.

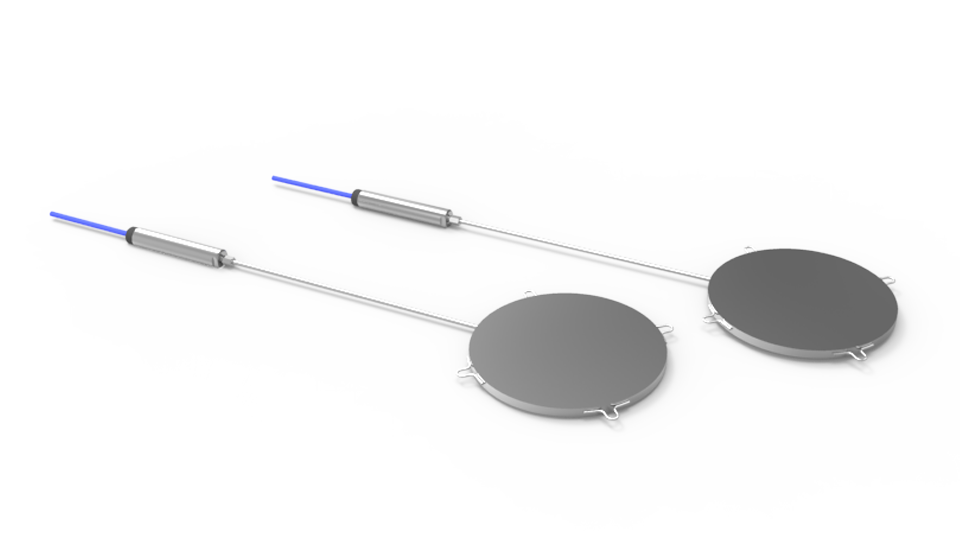

Total earth pressure cells consist of a single-sided sensitive pressure pad connected to the pressure transducer with a rigid steel tube. The pressure transducer is usually a vibrating wire sensor, due to the expected long life of this technology.

In tunnels, hydraulic pressure cells are often required to monitor stresses in the concrete lining. Hydraulic pressure cells are available in two models: radial pressure cells and tangential pressure cells. They must be customised in terms of pad shape, pad size, transducer model and measuring range. With this type of pressure cell, both local readings and remote monitoring are possible.

Flat jack pad is pressurized with oil which exerts pressure on the surrounding surface. By measuring the pressure required to lift the jack or the resulting displacement, engineers can assess the structural integrity and mechanical properties of the material being tested.

A lot of information, tips and limitations regarding the use of pressure cells can also be found in the international standard ISO 18674-5 “Stress change measurements by total pressure cells (TPC)”.