Extensometers

Extensometers are instruments used in geotechnical monitoring to measure the deformation or displacement of soil, rock, or other materials under various loads or conditions. They provide valuable data for assessing the behaviour and stability of structures, such as tunnels, buildings, bridges, slopes, and retaining walls. One of the most important application of extensometers is the dam rehabilitation.

The primary function of an extensometer is to quantify the change in length of a material along a specified direction. By attaching the extensometer to a specific point on the structure or within the ground, it can accurately measure the movement or deformation that occurs over time.

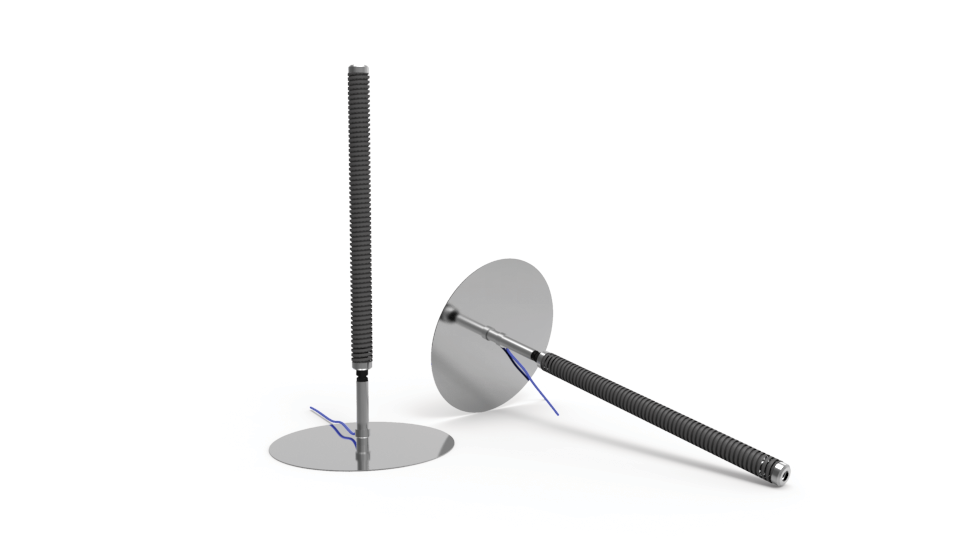

MPBX multipoint borehole extensometers (also called rockmeters) are often used when displacement measurement between a fixed point and two or more points on the same direction is required. They consist of an instrument head, up to 7 individual measuring rods of different lengths, each connected to a bottom anchor. Electrical or vibrating wire displacement transducers are installed in the head to enable remote monitoring. Alternatively, manual readings can be taken with a dial gauge. The measuring rods are available in different material to meet project requirements (fibreglass, stainless steel or invar steel).

The MEXID extensometer is a miniaturised version of the MPBX multipoint extensometer. Installation is permitted in a 50 mm diameter borehole. The MEXID extensometer is supplied fully assembled with pre-installed electrical or vibrating wire displacement transducers to enable very quick and easy installation. Simply unpack the MEXID, unroll it, insert the instrument into the borehole and grout.

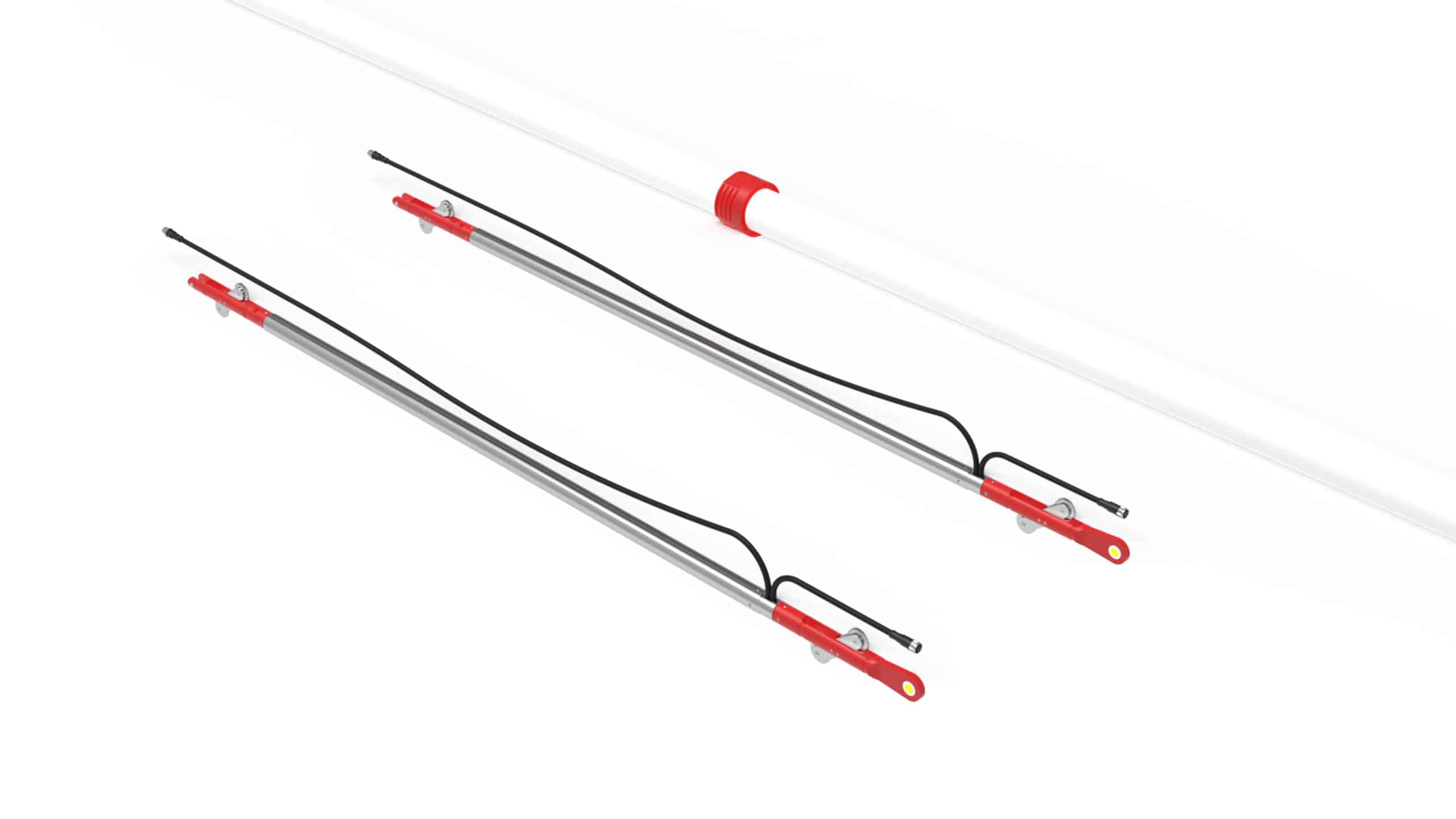

Embankment extensometers are installed in large earth structures like earth fill dams where monitoring of horizontal deformations within the dam body is requested. It consists of a number of anchor plates interconnected by telescopic sensed elements equipped with a displacement transducer to form a continuous chain for strain and deformation monitoring.

The T-REX incremental extensometer is able to detect meter by meter ground displacement with high accuracy. The guide tube is an ABS inclinometer casing with reference magnet rings installed at 1 meter spacing to each other. The incremental extensometer survey is taken with T-REX system. This system consists of the T-REX extensometer probe connected to BRAIN cable and managed through app by a portable device (Android or iOS). The T-REX system can be used not only vertically, but by using pushing-rods, in any direction.

DEX-S in-place extenso-inclinometers are equipped with two sensors: an extensometer sensor with the same operating principle as the T-REX extensometer, and a MEMS inclinometer sensor that can also measure probe inclinations. A chain of DEX-S probes installed inside a pipe, thus allowing both axial movements to the pipe and perpendicular movements to the pipe to be detected at various depths, returning a three-dimensional profile of the pipe.

The DEX-S in place extenso-inclinometers incorporates in addition to the DEX a built-in biaxial inclinometer sensor so that a DEX-S chain is able to provide 3-D borehole readings.

A lot of information and suggestions regarding extensometers can be found in the international standard ISO 18674-2 “Measurement of displacements along a line: Extensometers”.