Rogun Dam Hydropower Project

The Rogun Dam project in Tajikistan is an ambitious hydropower endeavor aimed at harnessing the Vakhsh River to generate renewable energy for the region. Originally launched in 1976 during the Soviet era, the project faced numerous delays due to financial and political challenges, especially after the dissolution of the Soviet Union. Construction was officially revived […]

Fuel terminal monitoring

Supply of instrumentation for the monitoring of fuel terminal tanks in the city of Cuenca, Ecuador. The scope includes the monitoring of the settlements of structures through H-Level settlement cells and tiltmeters. The settlements and horizontal movements of the ground will be evaluated through IPI inclinometer probes and DEX S probes.

Grand Paris Express

The Grand Paris Express is the largest urban project in Europe with the construction of 200 km of automatic lines, as much as the current metro, and 68 stations. The four new lines of the Grand Paris Express (15, 16, 17 and 18), as well as the line 14 extended to the north and south, […]

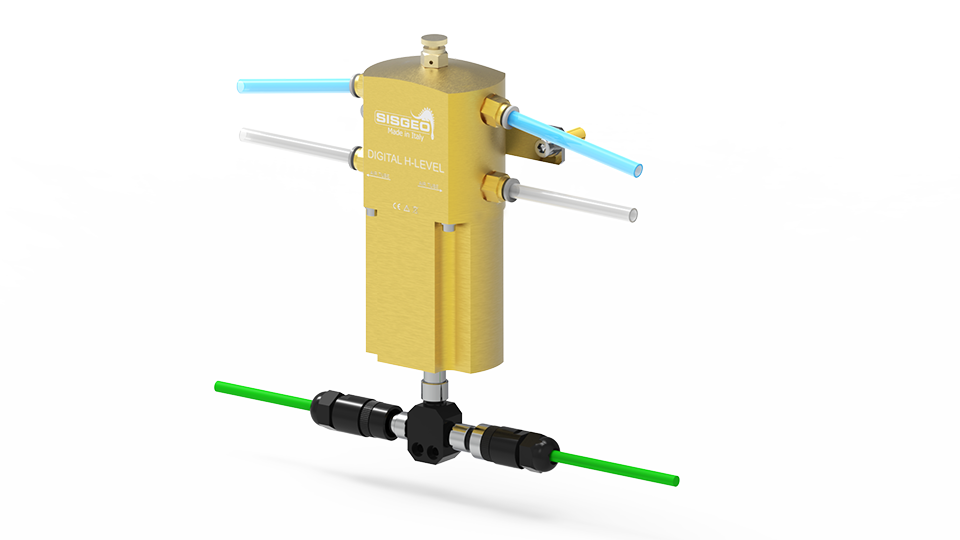

H-Level – Liquid Level Systems

Reference products codes: H-LEV The H-Level is the automatic liquid level system for accurate long-term monitoring of differential settlements in buildings, tunnels, and other civil structures. It consists of a series of H-Level gauges that are hydraulically connected to a reference tank positioned in a stable location. Each H-Level gauge includes a high-resolution pressure sensor […]

Milan Metro Line 4 – Lorenteggio–Linate – Monitoring of the underpass of railway trails RFI between stations “Forlanini Q.RE” and “Forlanini FS” – Italy

The main aims of the M4 realization are: to realize a new diametrical line from East to West, in order to connect through the historical center some highly populated urban areas that are not well served by the network of public transport; to interconnect with the whole railway system, urban and regional; to realize a […]

FAQ#116 – How do I configure a WR-Log digital node to read RS485 Sisgeo TIMED sensors?

Sisgeo digital instruments can operate in two powering modes: TIMED or ALWAYS-ON (for more information see F.A.Q.#094).A string of mixed instruments consisting of TIMED gauges and ALWAYS-ON gauges cannot work.The first thing to do is therefore to check that ALL connected instruments in your array are set to TIMED mode.You can check the powering mode […]

FAQ#111 – Why I cannot read correctly my 4-20mA current loop gauge?

It could be a problem connected to the power supply given by the readout or logger. When the power supply is in the current loop (2-wire gauge) it is necessary to consider the effect of voltage drop across the shunt resistor on the voltage applied to the gauge. For example, suppose a 4-20mA gauge requires […]

FAQ#095 – How long does a chain of digital sensors take to be read?

It mainly depends from the powering mode of the gauges (refer to FAQ#094 for the description of the powering modes). AN EXAMPLE WILL BETTER CLARIFY THE ANSWER. In a batch of 240 gauges, unless otherwise requested by the Customer, the addresses are settled from #001 up to #240. In a borehole is installed a chain of 30 […]

FAQ#076 – Why it is necessary add a termination resistor to the last digitized sensor of each RS-485 chain?

All SISGEO digitized instruments (IPIs, Tiltmeters, H-Level…) use the RS-485 serial communication protocol The RS485 protocol contemplate a termination resistor. The recommended chain connection is point-to-point (multidropped) nodes as a bus mode (line). Star, ring or multiply network connection are not recommended. SISGEO dataloggers has already a termination resistor assembled (typically 120Ω). On the opposite […]

FAQ#075 – What parameters are saved in SISGEO digital sensors? What information must the Customer provide when ordering?

All SISGEO digital sensors (e.g. IPI, BH Profile, MD Profile, LT Inclibus, Tilt-meter, RDS, H-Level, etc.) use the Modbus communication protocol over RS-485 serial. SISGEO digital sensors are connected to each other with a single signal cable. The parameters that are configured at the factory for each digital sensor are as follows: Upon confirmation of […]

FAQ#074 – Which kind of datalogger is necessary to read a SISGEO digital sensors?

The sensors are read connecting the end cable to a Modbus Master unit (i.e. OMNIAlog or miniOMNIAlog) with RS-485 interface (DCE, Half duplex, no Echo) able to manage communication with SISGEO Modbus RTU communication protocol. SISGEO’s communication protocol is available for the release upon request. The power [W] of power supply must be chosen according […]

FAQ#073 – Which is the maximum number of digitized sensors (RS-485, Modbus), the maximum number of chains and the maximum length of cable in a RS-485 network?

Last update: October 2021 All the SISGEO digitized sensors utilize a RS485 interface with Modbus protocol. 1.The maximum number of digitized sensors in a RS-485 network are 247 (theoretical) 2.The maximum number of digitized sensors chains that is possible to connect to Modbus master unit (as OMNIAlog or miniOMNIAlog) are 4. 3. About the maximum […]