What is SHM - Structural health monitoring?

Structural Health Monitoring (SHM) is a process of continuous or periodic monitoring of the condition of a structure to detect any changes in its properties or behaviour that may indicate the onset of damage or failure.

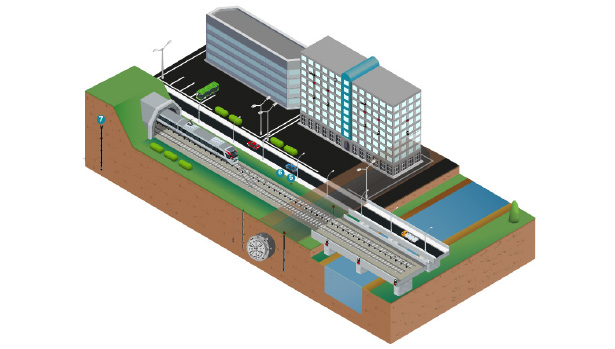

In the context of structural engineering, SHM involves the use of sensors and data acquisition systems to collect and analyse data related to the structural response of a building, bridge, dam, tunnel or other infrastructure system. This data is used to detect and assess any changes in the structural response over time that may indicate damage or deterioration.

The goal of SHM is to provide early warning of potential structural problems, allowing for timely intervention and maintenance to prevent catastrophic failures, reduce repair costs, and extend the lifespan of the structure.

Which are the challenges?

The main monitoring topics and challenges in SHM can vary depending on the type of structure being monitored, but some of the common topics and challenges include:

- Gauge selection and installation: the placement of instrumentation is critical in SHM to ensure accurate and reliable data collection. However, selecting the right sensors and determining their optimal placement can be challenging, especially for complex structures. Sisgeo skilled engineers can help the designers and building company to select the right instrumentation set.

- Data acquisition and processing: the data collected from sensors must be processed and analysed to identify any changes or anomalies in the structure’s behaviour. Sisgeo can propose an advanced web platform for data treatment and reporting.

- Damage detection and identification: the ability to detect and identify any damage or degradation in a structure is a key objective of SHM. However, distinguishing between damage and normal variations in the structure’s behavior can be challenging.

Overall, the main challenge in SHM is to develop reliable, accurate, and cost-effective monitoring system that can provide early warning of potential structural issues and enable effective maintenance and repair activities.