Load cells

Load cells play a critical role in assessing the performance, safety, and reliability of structures and geotechnical systems by measuring and monitoring loads and forces accurately.

Load cells are commonly used to monitor the load applied to anchor rods, the load applied to piles or struts, and for measuring the force distribution in steel lining (tunnelling). Other applications are retaining walls, deep excavations, dams, foundations and bridge abutments.

Load cells enable engineers to make informed decisions regarding design optimization, maintenance, and structural health monitoring.

Hydraulic anchor load cells are basically a ring-shaped pad filled with deaerated oil and connected to a Bourdon gauge that indicates the load applied to the cell.

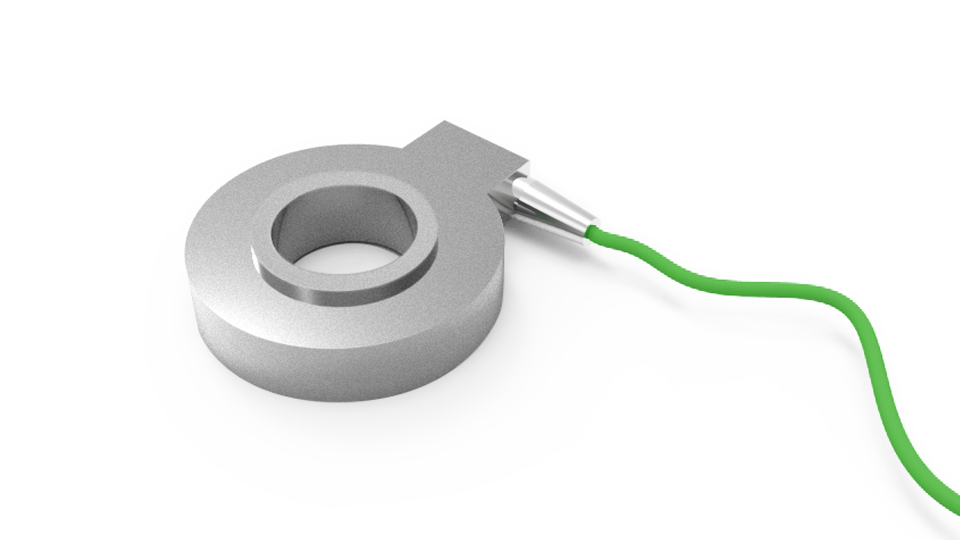

Electric anchor load cells consist of a stainless-steel toroidal body sensed with electrical resistance strain gauges, in a Wheatstone bridge configuration, to ensure, together with the particular cell design, very low sensitivity to eccentric loads.

Both electric and hydraulic models are supplied with a very rigid load distribution plate to distribute the force around the instrument body. Anchor load cells of different sizes and measuring ranges are available to meet customer requirements.

Steel lining load cells are specially designed to be installed under steel linings to control the transmission of applied load from the surrounding rock/soil to the beam. They are circular pads, filled with deaerated oil and measured with an electrical pressure transducer. This load cell model is available with special twin spherical plates for application between non-parallel surfaces.

Solid resistive load cells are very robust and designed for long-term stability. They can be used in pile load tests or any other project where a wide measuring range is required.