Piezo-Resistive piezometers

Their robust 4-20mA output signals are easy to read and automate with OMNIAlog and suitable for long-distance transmissions.

They can be connected to seismic dataloggers for monitoring rapid changes in pore-water pressure such as those produced by earthquakes.

APPLICATIONS

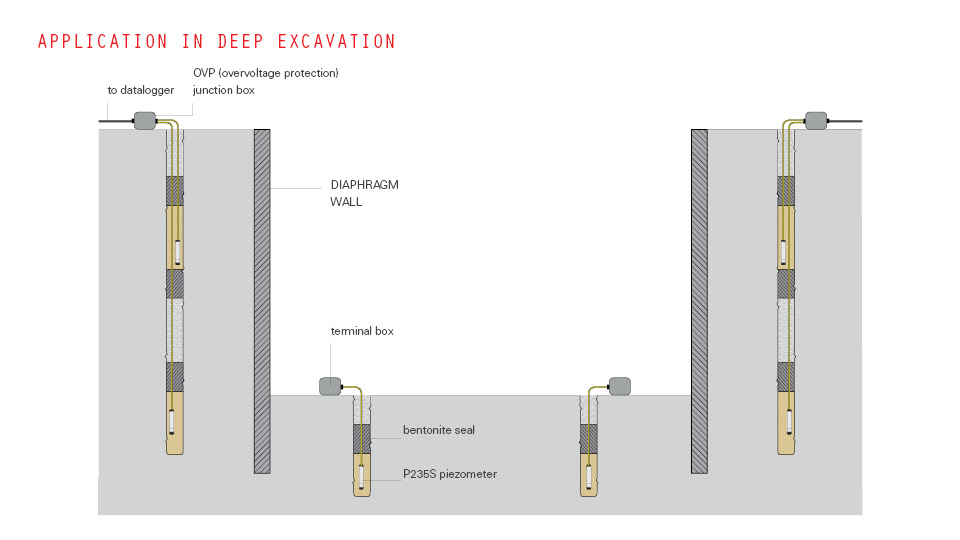

• Pore pressure in deep excavations

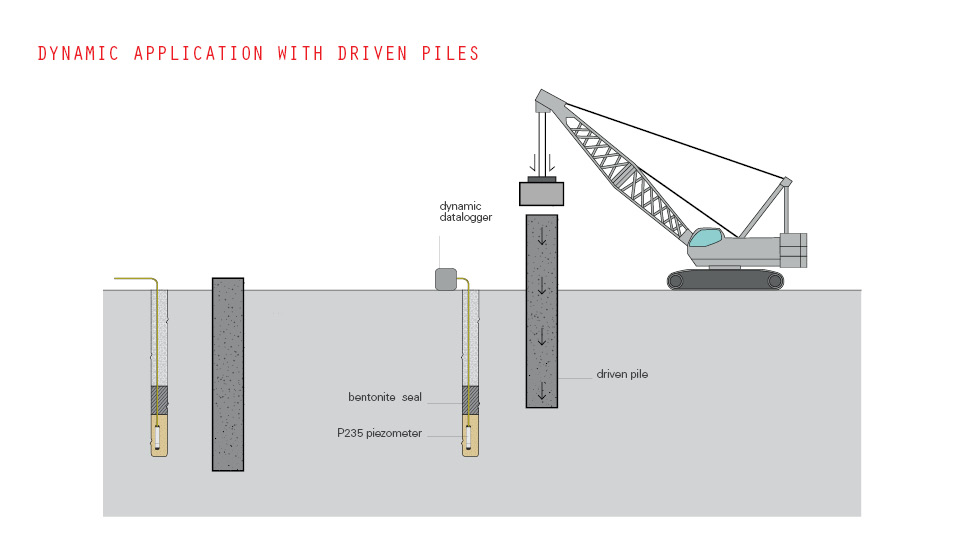

• Dynamic pore pressure monitoring

• Dewatering activities

• Hydraulic gradients in natural or cut slope

FEATURES

• High accuracy and stability

• Compatible with most readout/logger in the market

• Built-in thermistor (on request)

• Capable of reading negative pressures

Resistive pressure transducer sensor is a spin off from thick film technology using the piezo-resistive characteristic of specific resistive inks. Resistors, formed using screen printing techniques, are deposited on a deformable ceramic diaphragm substrate to form strain gauge arrays. Strain changes from external loads applied to the deformable ceramic diaphragm result in resistance changes of the strain gauge arrays.

The electric signal from the strain gauge arrays is directly proportional to the stress applied to the diaphragm. Sensor is constructed of a ceramic, analogous to a crystal structure, to form a pressure diaphragm chemically inert with near perfect mechanical characteristics. Screen printed resistors are deposited onto the diaphragm to form a 4 arms Wheatstone bridge.

A fixed excitation voltage is applied to one diagonal of the circuit. Strains experienced by the diaphragm will change the values of the individual resistors within the Wheatstone bridge resulting in a bridge unbalance. This unbalance produce an output signal from the other diagonal of the Wheatstone bridge, directly proportional to the applied stress.

An electronic board converts this signal into 4-20 mA suitable for transmission over long distances to remote readouts or to data acquisition systems.

Readable by