Spot Weldable Strain Gauges

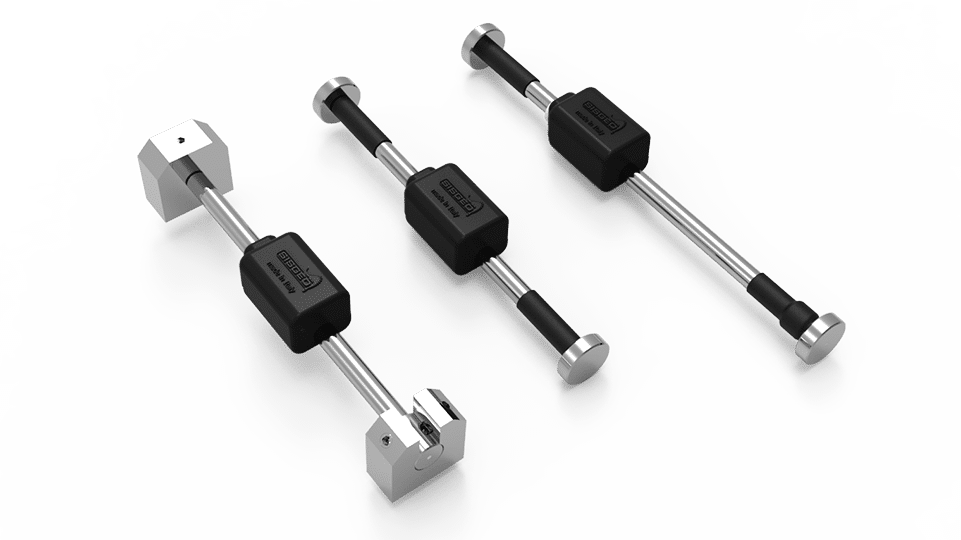

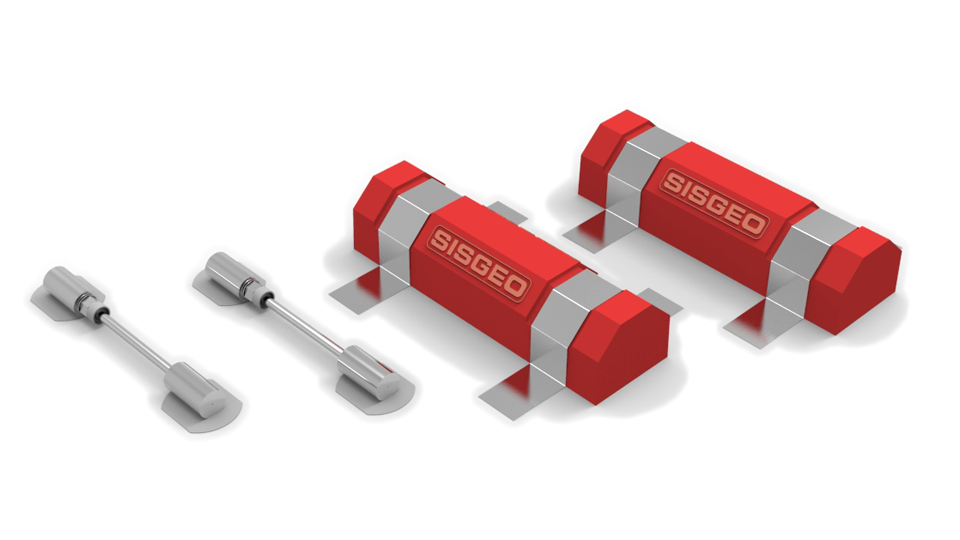

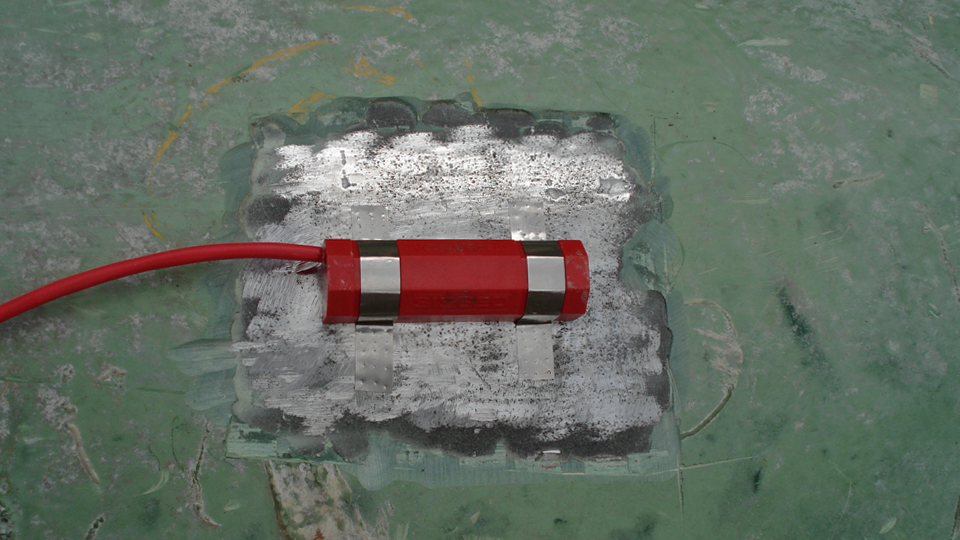

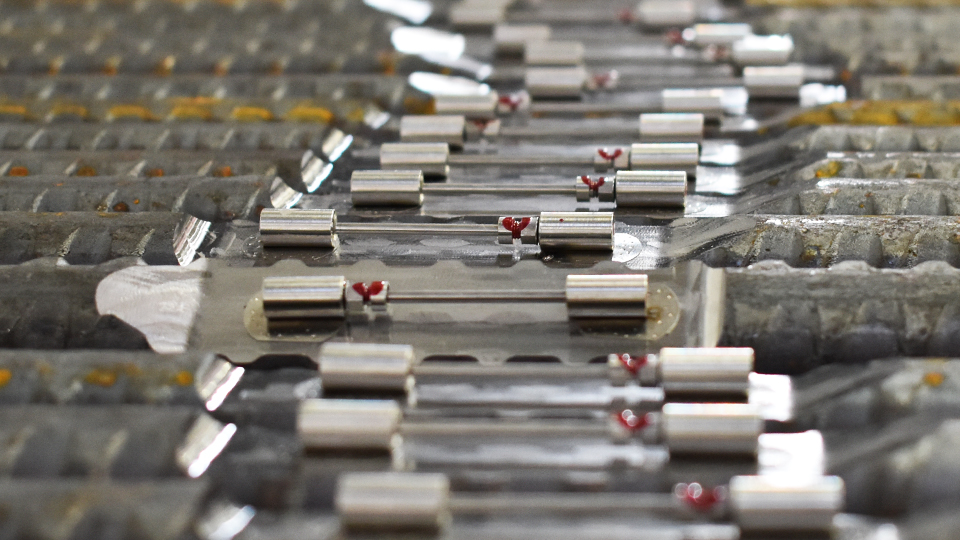

Spot weldable strain gauges are designed for application on steel structure or reinforcement bars where strain monitoring is required and the installation space is limited.

They are mainly composed by a vibrating wire sensor placed between two small spot-weldable plates; the gauge shall be fixed to the metal surface using a spot-welder. The reading is obtained by placing the instrument red cover containing the coils for wire exciting and signal reading. An NTC thermistor sensor is built-in into the cover.

The sensor is pre-tensioned at mid-scale: at order time, Customer can choose the pre-tension desired

Vibrating wire transducer is essentially composed by a taut wire clamped at its ends and tensioned so that it is free to vibrate at its natural frequency. The frequency of vibration varies with the wire tension and thus small relative movements between the two end clamps.

With vibrating wire transducers frequencies rather than voltage levels are measured, so a dedicated readout/datalogger must be used to measure the resonant frequency. These ones excites the vibrating wire transducer, measures the response, performs some calculations on the response, and returns the result.

SISGEO vibrating wire transducer uses ‘pluck and read’ method and not ‘auto resonant’ method; when the readout/datalogger plucks the wire a magnetic attraction is created to the coil and the wire start to vibrate and it causes an alternating voltage of the same frequency of the natural frequency of the wire; the voltage signal is transmitted on the cable and read from the readout/datalogger.

Vibrating wire transducers have a reputation for long expected life and long-term stability.

Readable by

Questions

about this

product?

about this

product?

Questions

about this

product?

about this

product?

Learn more

Datasheet

Manual

Faq