MEMS In-place Inclinometers

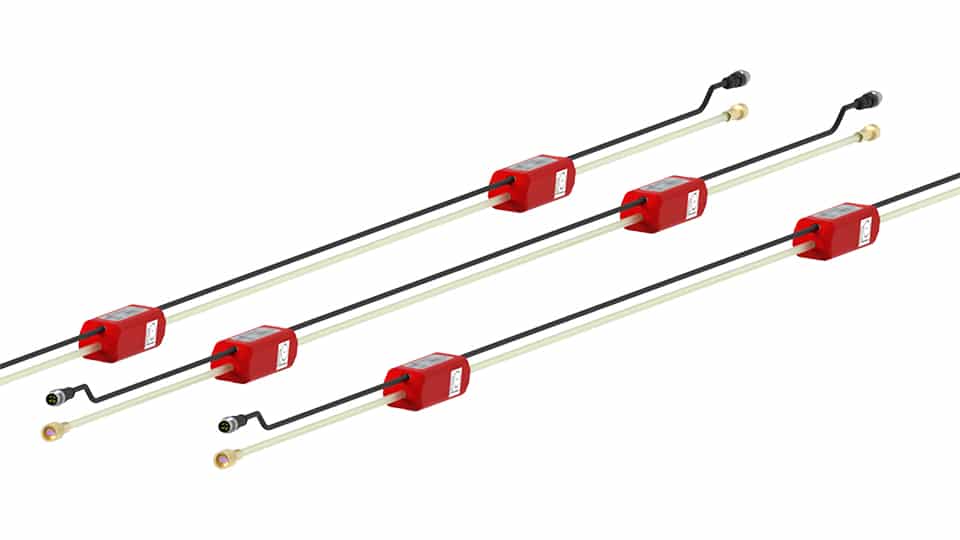

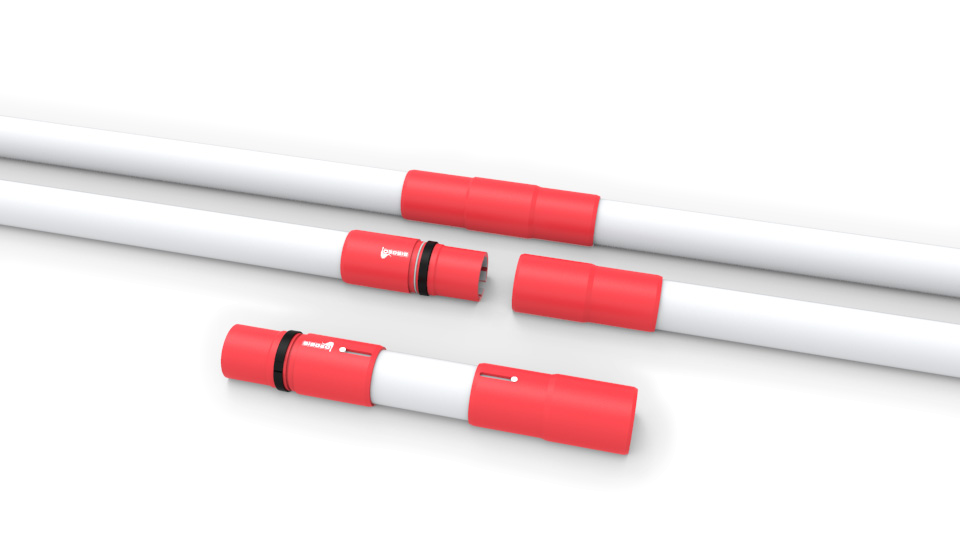

Reference products codes: S411HA, S412HA, S411HD, S412HD

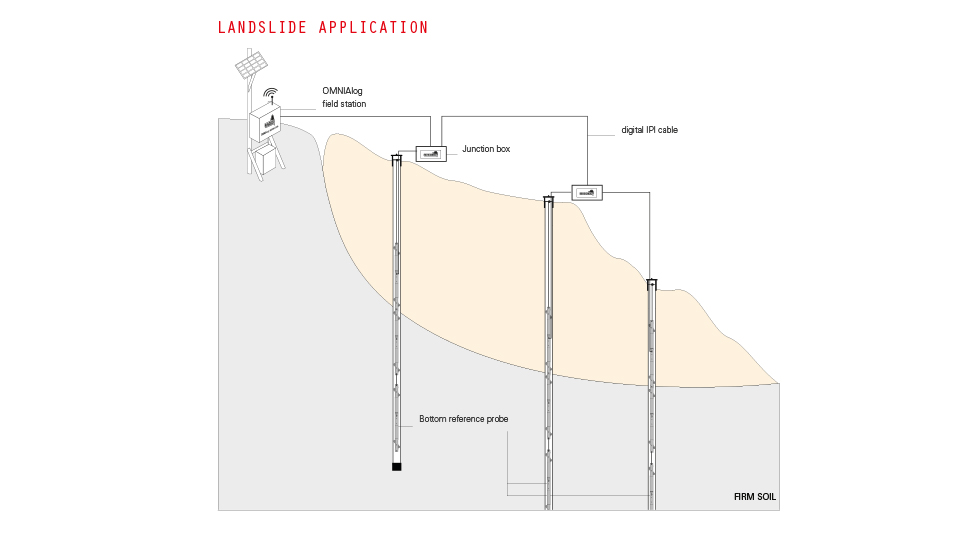

MEMS In-place inclinometer (IPI) sensors are designed for automatic monitoring of critical locations.

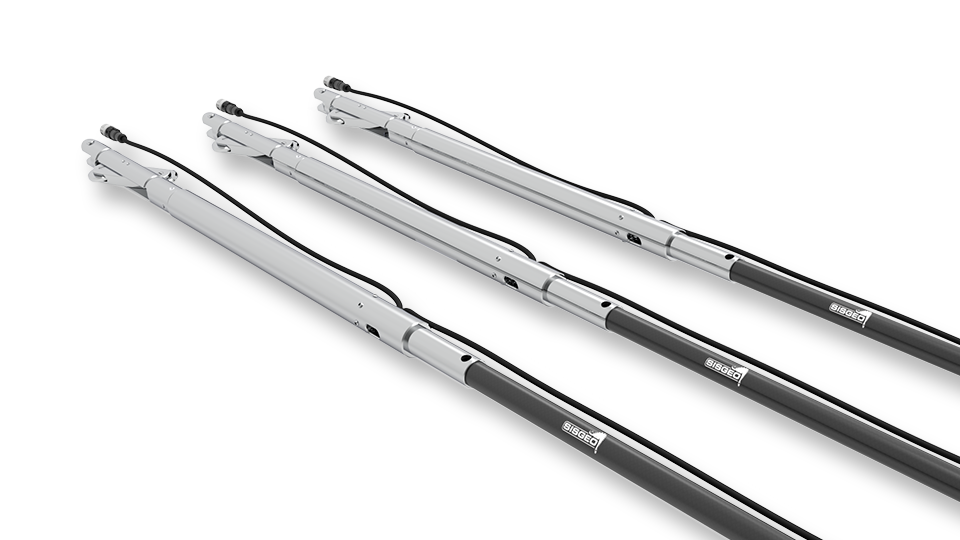

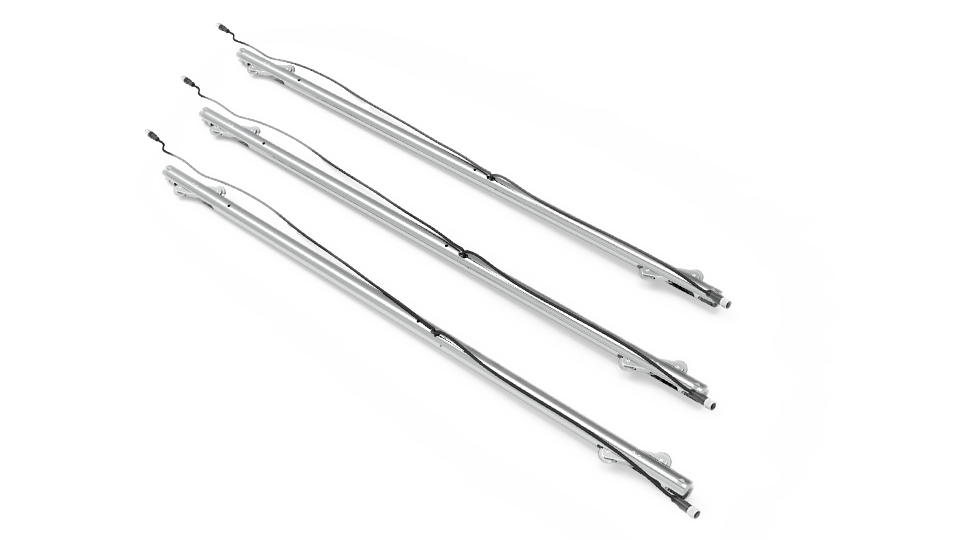

Connected to each other via a steel wire and suspended inside inclinometer casings at certain depths, this chain of IPIs allows horizontal deformation to be monitored at the depths where they are positioned.

Vertical in-place inclinometers can be sensed with uniaxial or biaxial MEMS tilt sensor that grant great performance for both accuracy and thermal drift.

The digital version utilizes the Modbus RS485 serial communication protocol: this technology allow to use only one cable to connect all the probes in one chain.

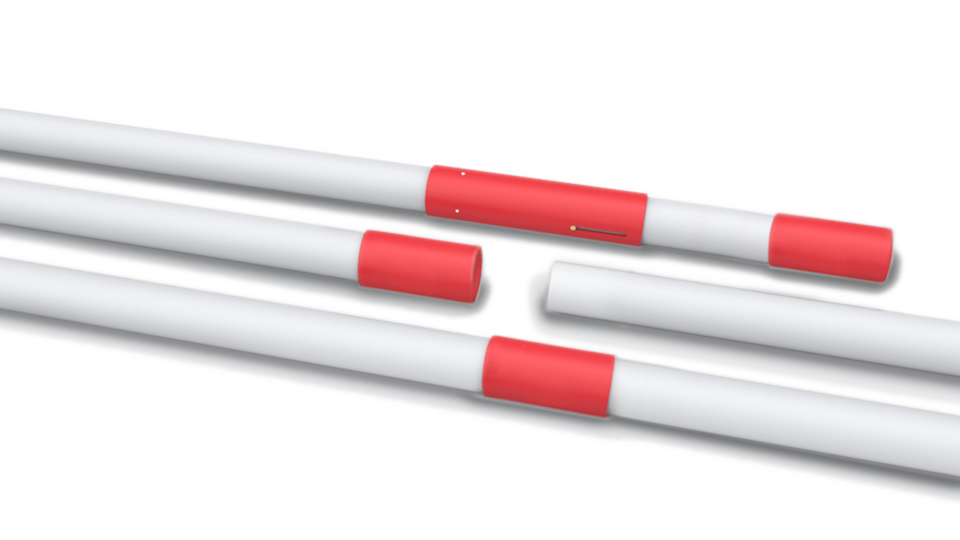

MEMS in-place inclinometers are compatible with all Sisgeo’s inclinometer casings: standard, Easy Lock and Quick Joint

Inclinometer tube may be also automatically monitored with a continuous chain of BH Profile inclinometers.

Tiltmeters are instruments that measure angles respect to the gravity acceleration vector. To get this result an accelerometer is required. It measures the projection of acceleration gravity on its sensing axis. Sensor can have 1, 2 or even 3 sensing axes.

The MEMS (Micro Electro Mechanical Systems) implementation of accelerometers it’s pretty young (about 20years) but mature enough to have its strong reliability been proven. MEMS are indeed silicon chips machined to create a mechanical part inside. The required electronic to read out the signal is inside the same chip.

The working principle is a spring-mass system: a mass (rotor) is anchored with springs to a fix frame (stator). When an acceleration occurs, the rotor moves respect to the stator loading or unloading the springs. That’s it: the displacement measurement is proportional to the applied acceleration. Displacement is measured with different technologies inside the chip but in its simplest form is related to a capacitance measure.

Sisgeo uses the state-of-the-art of MEMS accelerometers that implement several methods to compensate temperature variation and reduce the cross-axis error reaching very high accuracy.

Readable by

Questions

about this

product?

about this

product?

Datasheet

Manual

Data processing

Faq

Questions

about this

product?

about this

product?

Datasheet

Manual

Data processing

Faq