What is truss metal bridges monitoring?

Truss metal bridge is a type of bridge that uses a series of interconnected triangles to support the bridge deck and transfer loads to the abutments or piers. The truss is a framework of metal bars or tubes that are arranged in a series of triangles, which are known for their strength and stability.

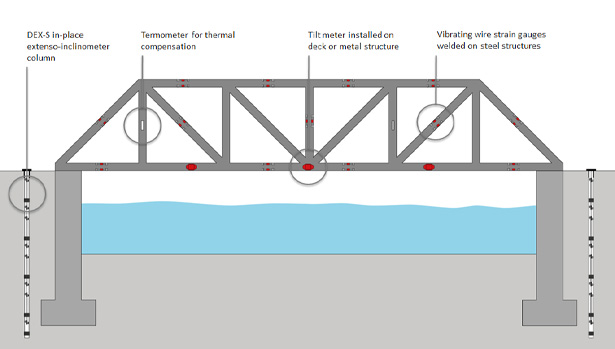

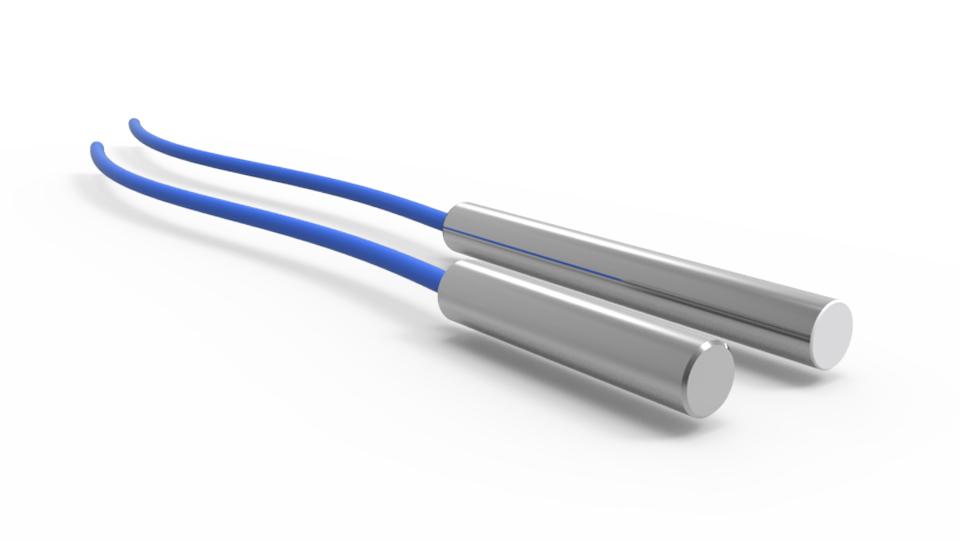

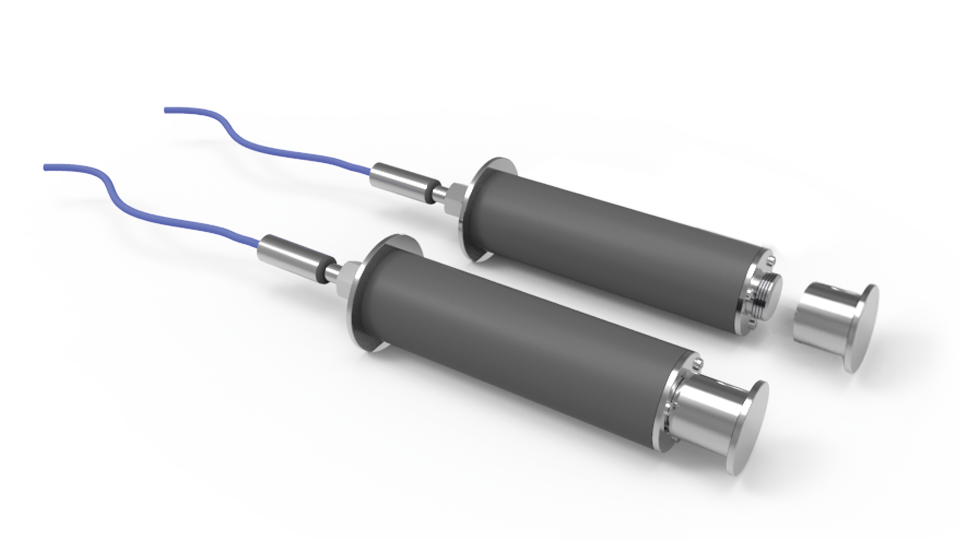

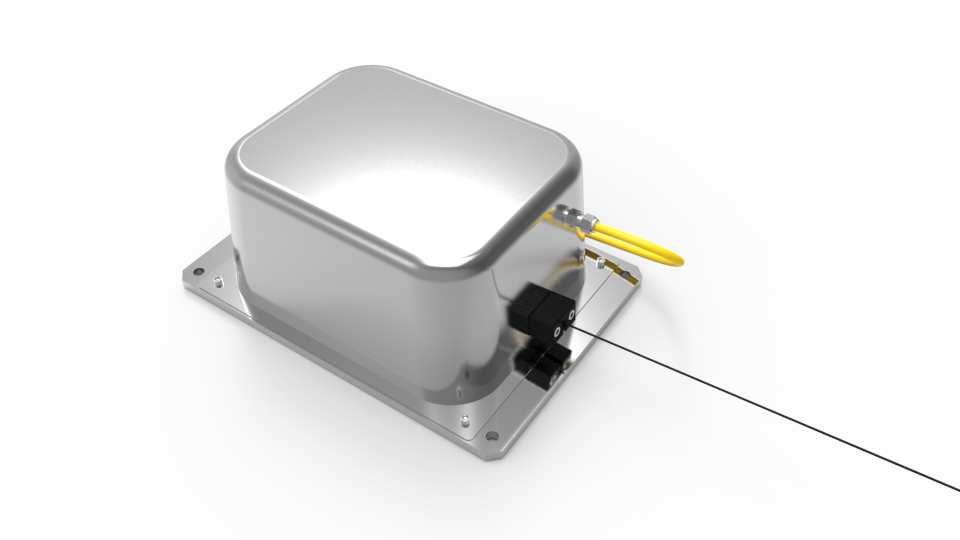

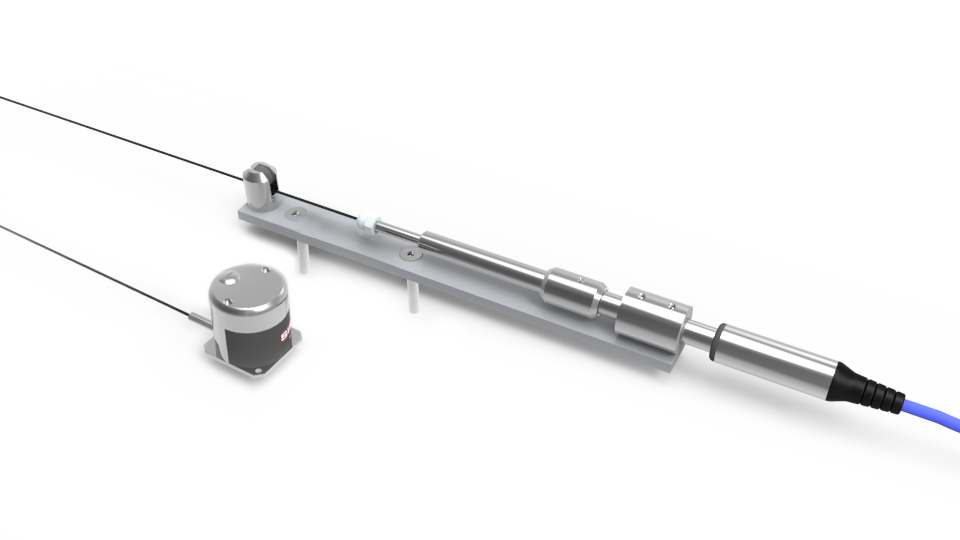

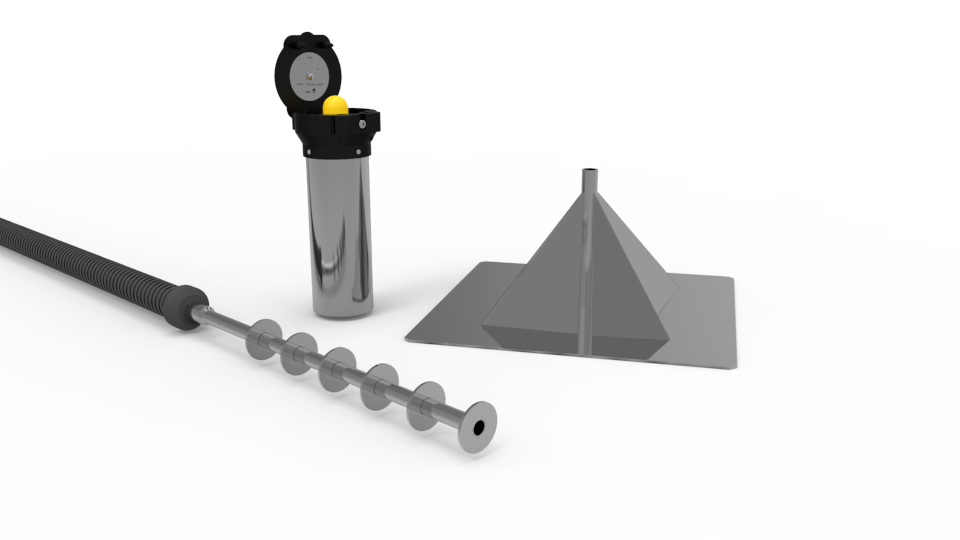

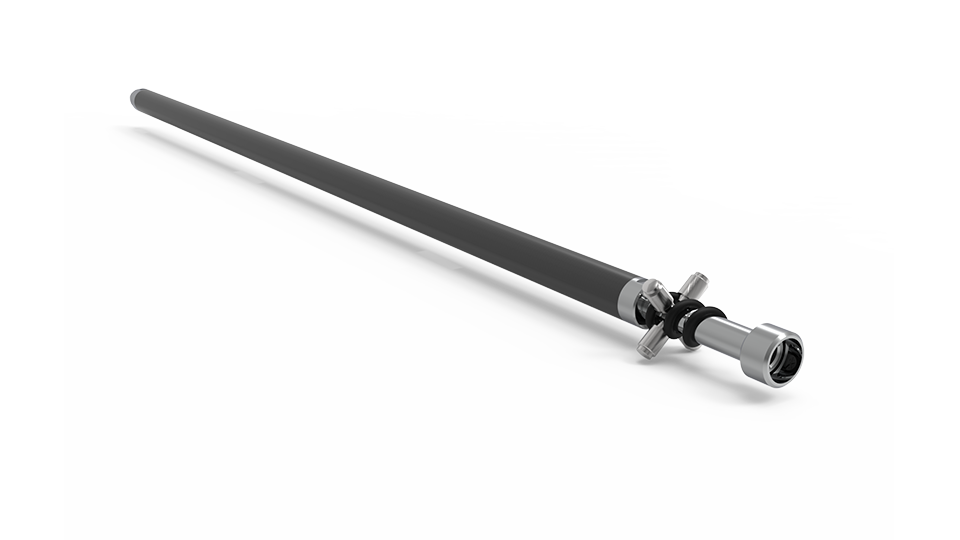

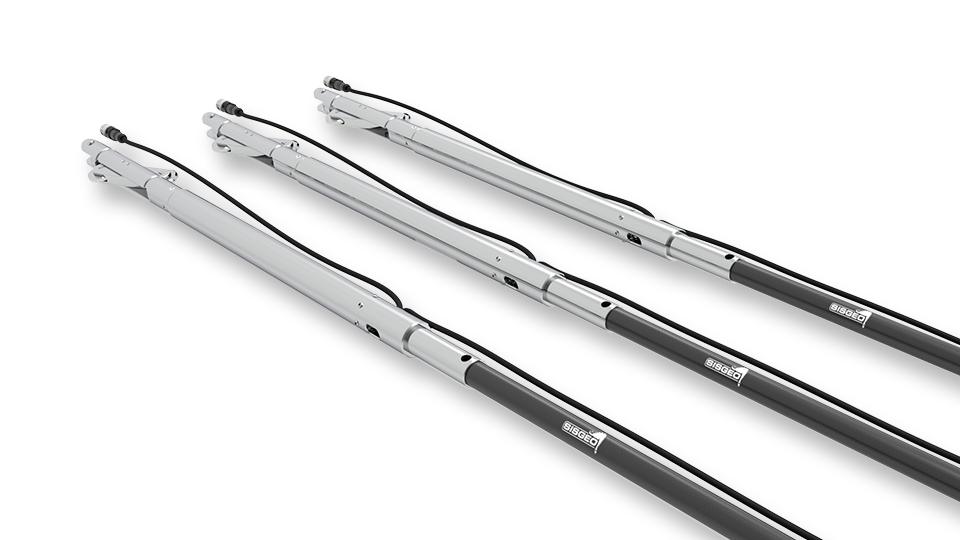

Geotechnical monitoring involves assessing the stability of the foundation of the truss metal bridge, which is critical for ensuring the bridge’s long-term performance and safety. This may involve monitoring the behaviour of the soil and rock underneath the bridge with borehole instrumentation such as inclinometers, in-place inclinometers, MPBX multipoint extensometers, piezometers, or DEX-S in-place extenso-inclinometers. This helps engineers to detect any soil movement or instability, which can cause damage to the bridge or lead to failure.

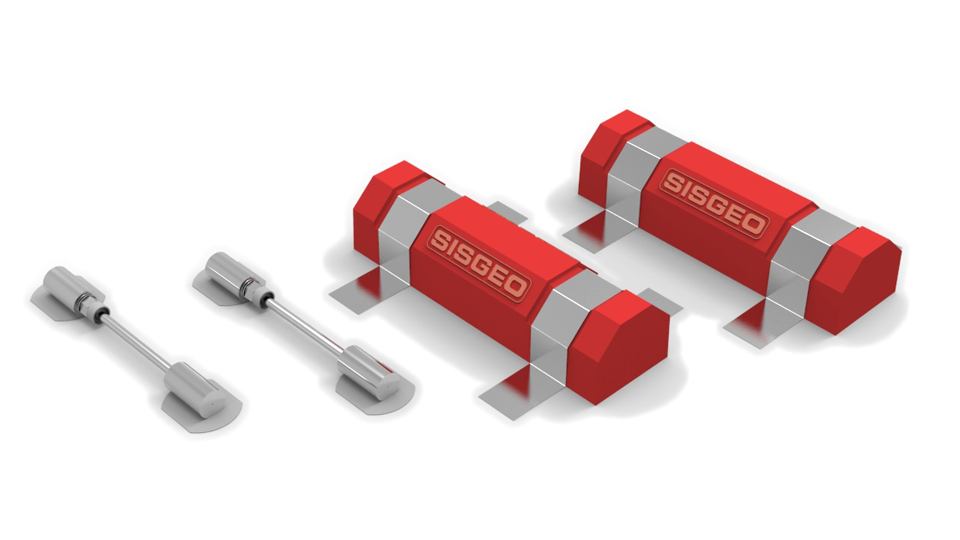

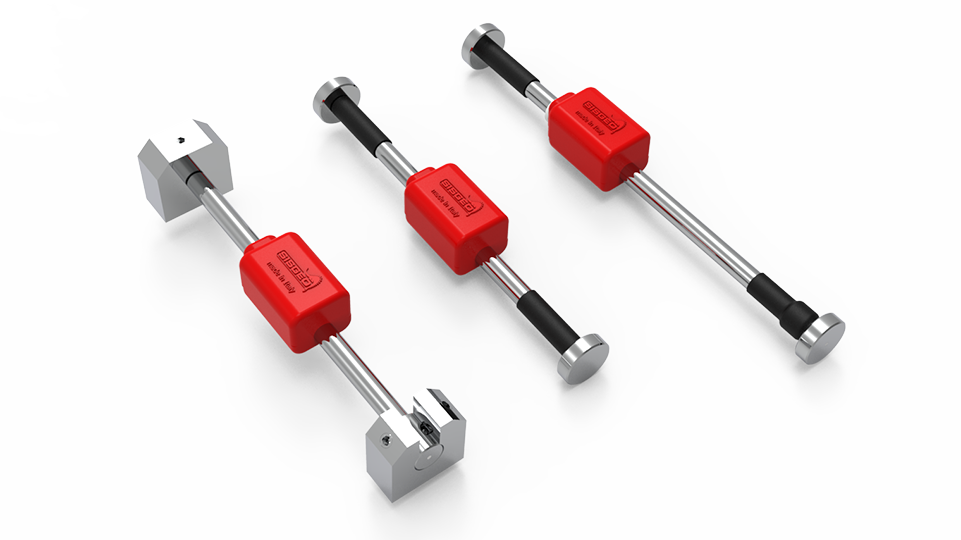

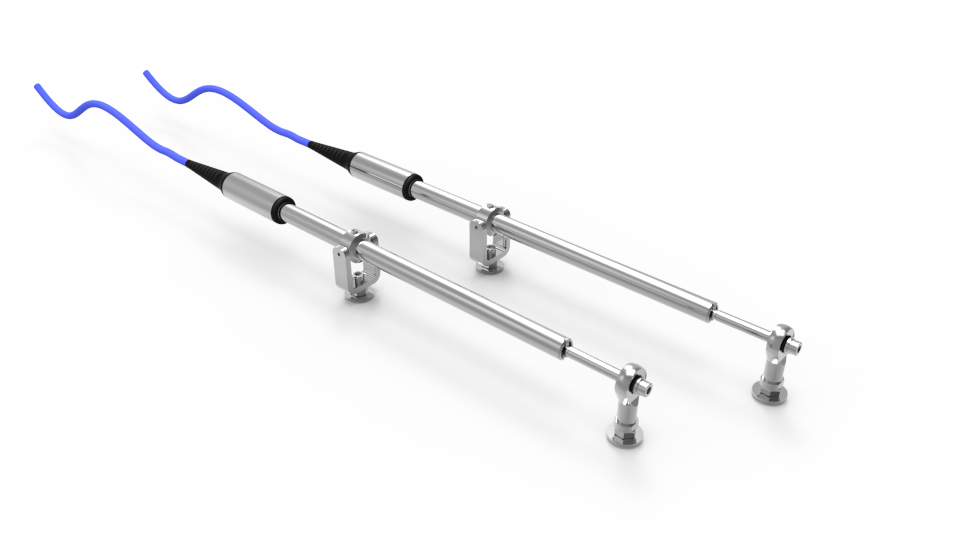

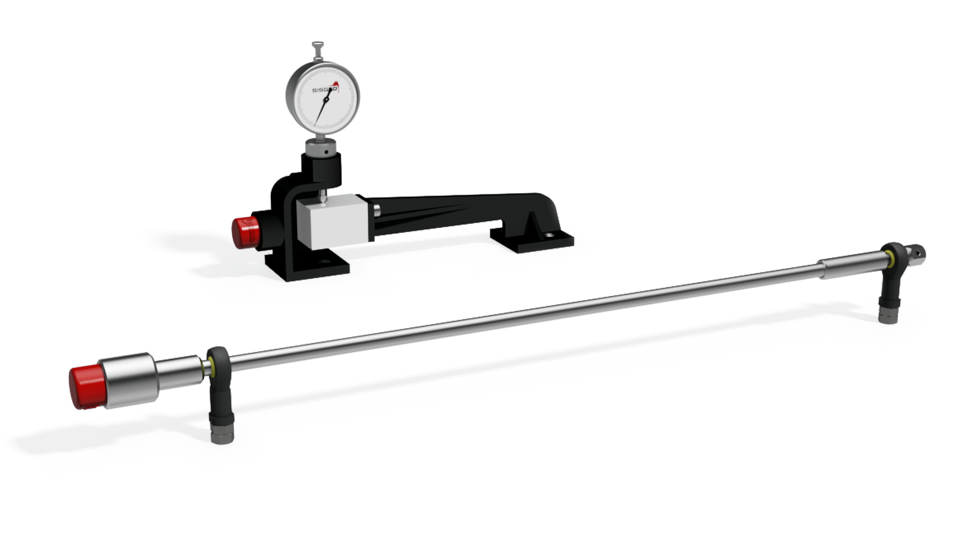

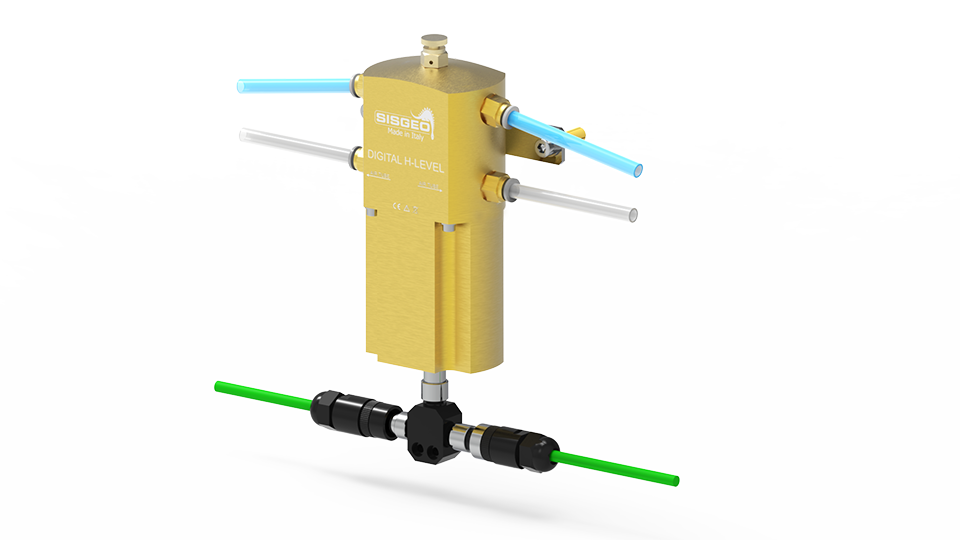

Structural monitoring involves assessing the condition and performance of the bridge’s superstructure, including the truss members, deck, and bearings. This involves instruments like strain gauges, tilt meters, LT-Inclibus string of tiltmeters, H-Level settlement gauges, crack meters and displacement sensors.

By regularly monitoring both the geotechnical and structural aspects of truss metal bridges, engineers can identify any potential issues early on and take proactive measures to maintain and repair the bridge, ensuring its long-term safety and reliability.