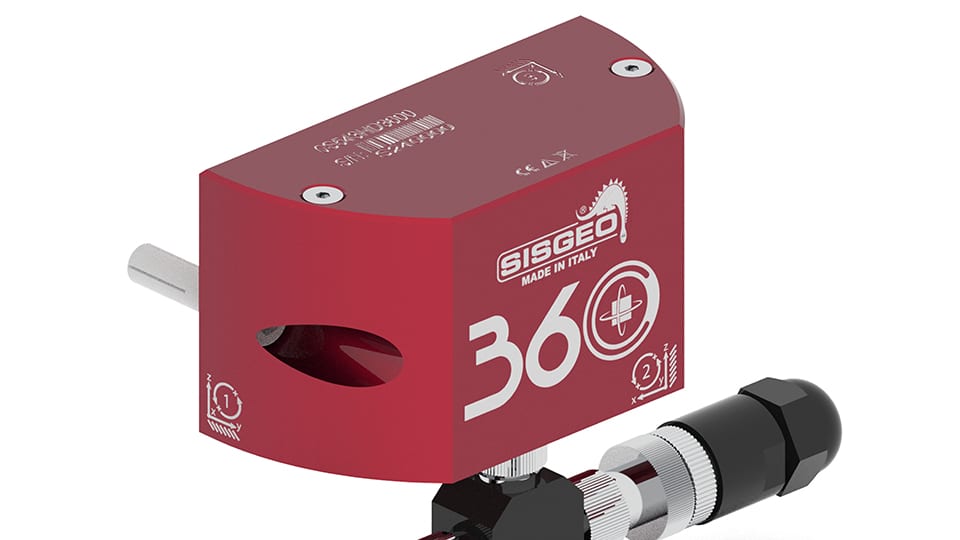

360° DIGITAL MEMS TILTMETER

Reference products codes: 0S543HD3600

The 360° MEMS Tiltmeter is specifically designed for applications that demand high accuracy and minimal thermal drift, without concerns regarding instrument positioning.

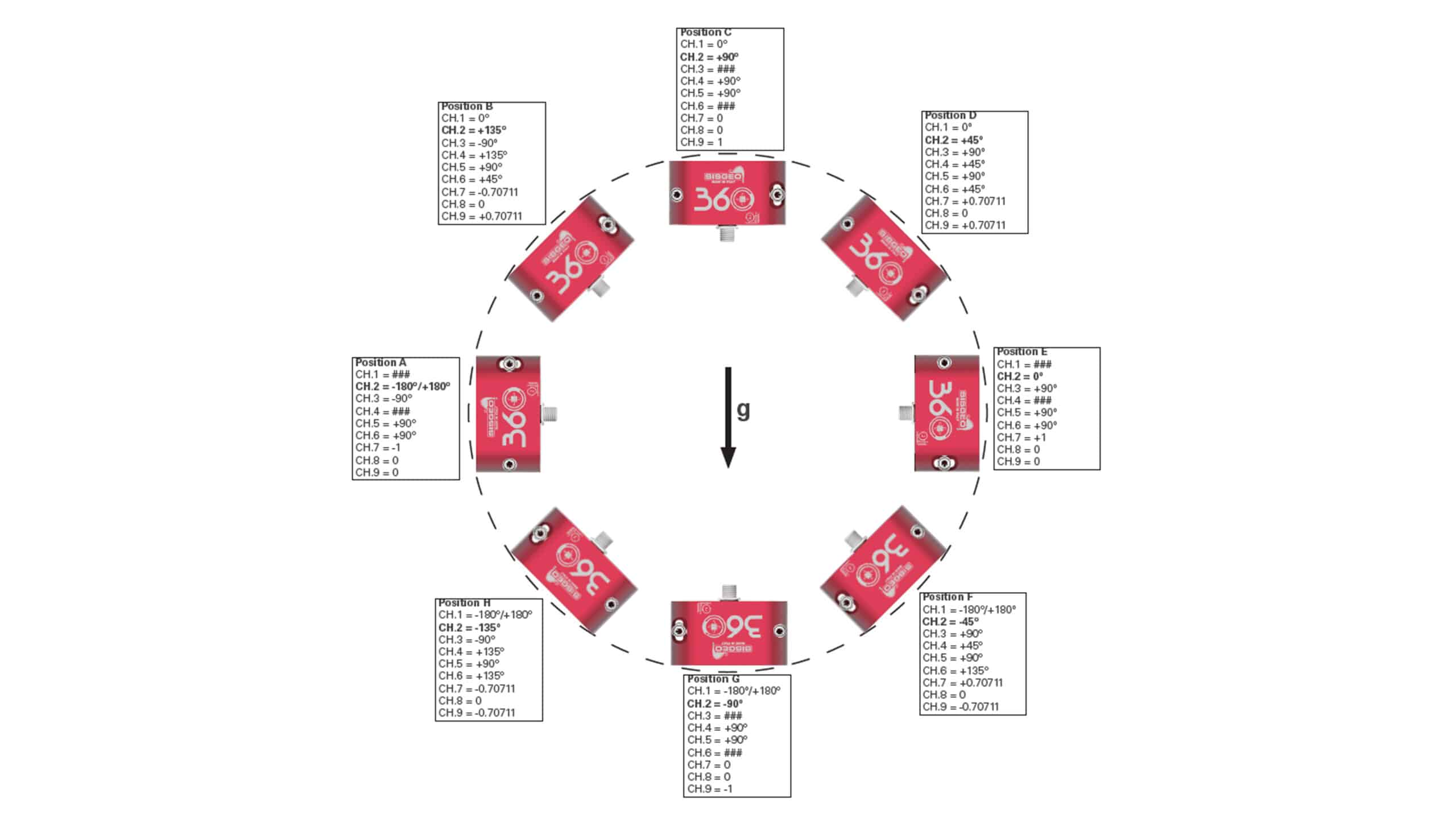

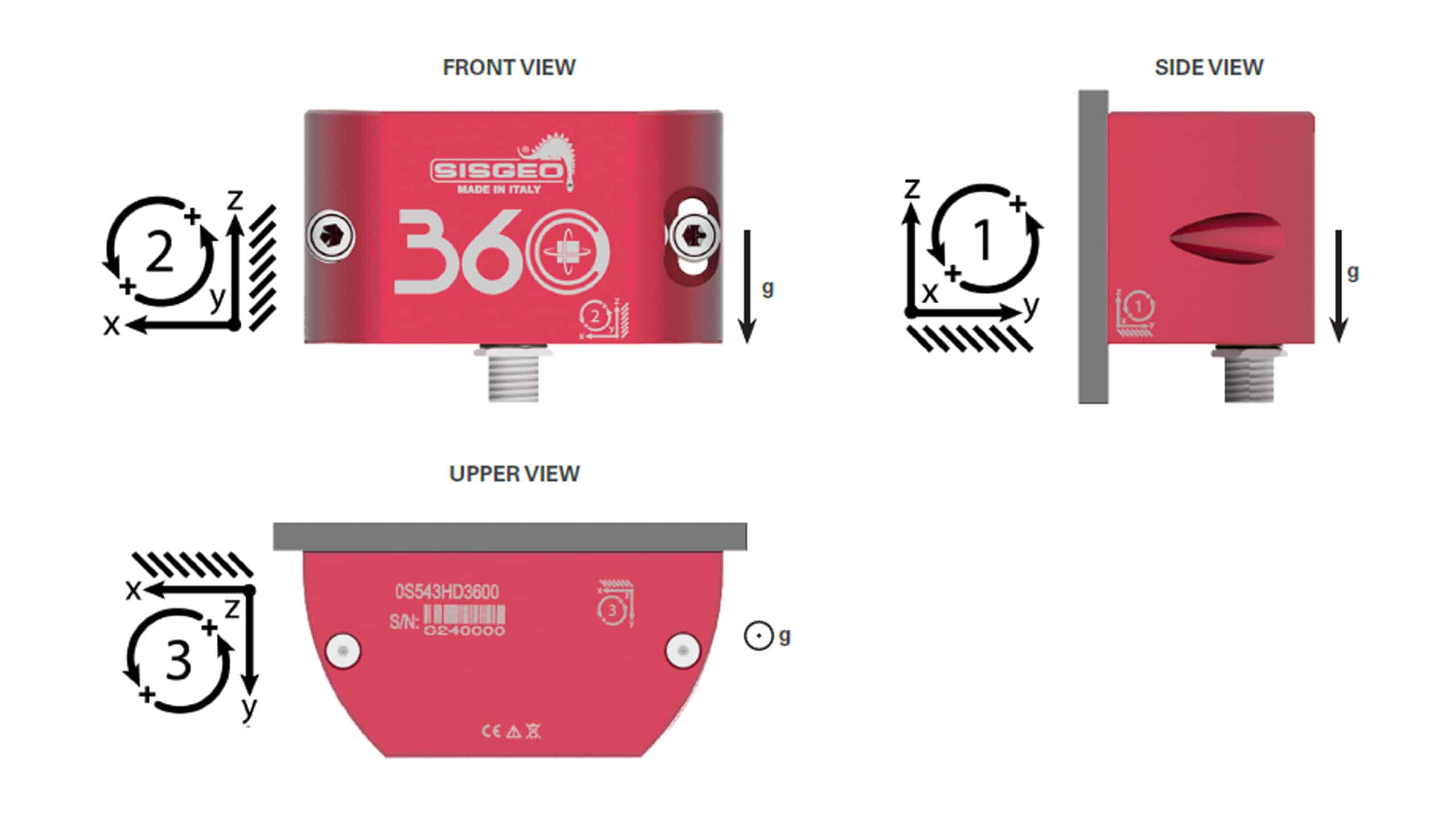

Thanks to 360° technology, each MEMS tiltmeter can be calibrated across the full 360° range on three axes. This feature enables the instrument to be installed in any orientation, without impacting measurement quality, which simplifies installation operations significantly.

Furthermore, the 360° technology allows the same instrument to be removed and reinstalled on surfaces with varying inclinations and orientations, thus enhancing the tiltmeter’s versatility.

In addition, the latest MEMS technology, combined with Sisgeo’s custom electronic components, ensures exceptional performance and reliability.

For data collection, 360° MEMS tiltmeter offers various reading options: local reading via the MIND portable readout, a wireless connection using the WR-Log node, or centralized data collection with the OMNIAlog datalogger for remote monitoring.

As a result, the 360° MEMS tiltmeter provides a comprehensive and transparent data set in engineering units (sexagesimal degrees). Additionally, each instrument offers raw data in terms of calibrated accelerations along the x, y, and z axes, in case the user wishes to calculate inclinations or rotations using alternative algorithms.

Tiltmeters are instruments that measure angles respect to the gravity acceleration vector. To get this result an accelerometer is required. It measures the projection of acceleration gravity on its sensing axis. Sensor can have 1, 2 or even 3 sensing axes.

The MEMS (Micro Electro Mechanical Systems) implementation of accelerometers it’s pretty young (about 20years) but mature enough to have its strong reliability been proven. MEMS are indeed silicon chips machined to create a mechanical part inside. The required electronic to read out the signal is inside the same chip.

The working principle is a spring-mass system: a mass (rotor) is anchored with springs to a fix frame (stator). When an acceleration occurs, the rotor moves respect to the stator loading or unloading the springs. That’s it: the displacement measurement is proportional to the applied acceleration. Displacement is measured with different technologies inside the chip but in its simplest form is related to a capacitance measure.

Sisgeo uses the state-of-the-art of MEMS accelerometers that implement several methods to compensate temperature variation and reduce the cross-axis error reaching very high accuracy.

Readable by

Questions

about this

product?

about this

product?

Learn more

Datasheet

Manual

Modbus

Data processing

Faq

Questions

about this

product?

about this

product?

Learn more

Datasheet

Manual

Modbus

Data processing

Faq