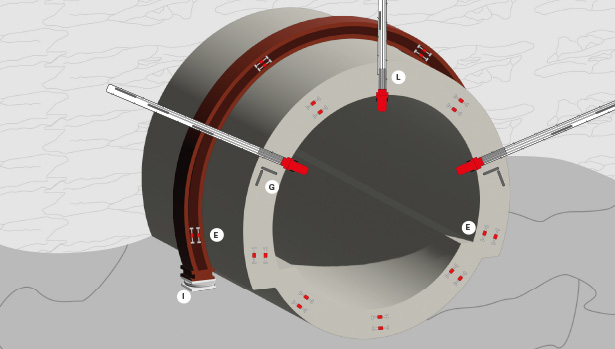

What is NATM Tunnel monitoring?

The New Austrian Tunneling Method (NATM), also known as the Sequential Excavation Method (SEM), is a technique used in the construction of tunnels that was developed in Austria in the 1960s. NATM involves excavating the tunnel in stages, with the surrounding rock or soil providing temporary support until a permanent lining is installed.

Monitoring is one of the most important steps in NATM method: the stability of the surrounding rock or soil is continuously monitored during the excavation process to ensure the safety of workers and the stability of the tunnel.

NATM tunnel monitoring involves the continuous measurement and analysis of various parameters related to the construction and operation of a tunnel built using the New Austrian Tunneling Method (NATM).

During the construction phase, monitoring is typically focused on assessing the stability of the surrounding rock or soil, as well as the performance of the initial support measures and the excavation process itself. Here are some key parameters that can be monitored during construction:

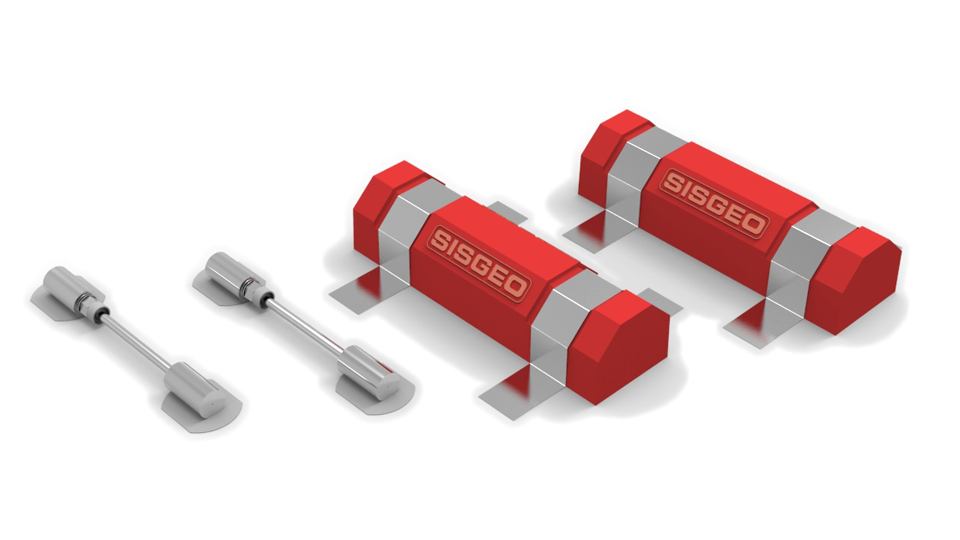

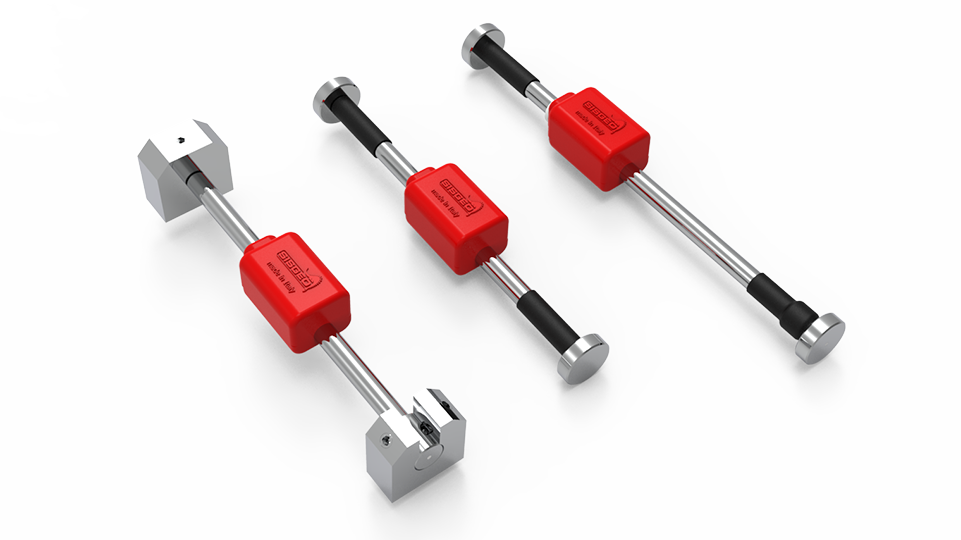

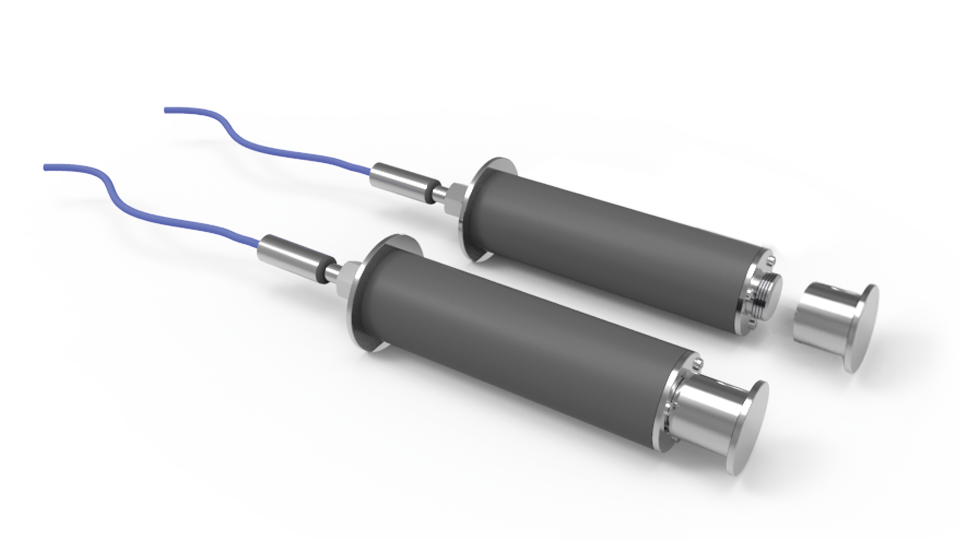

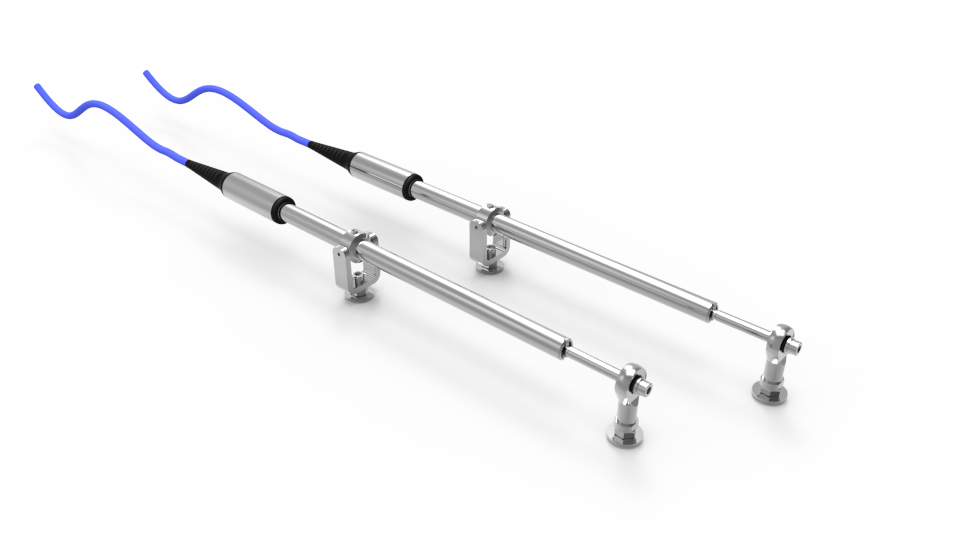

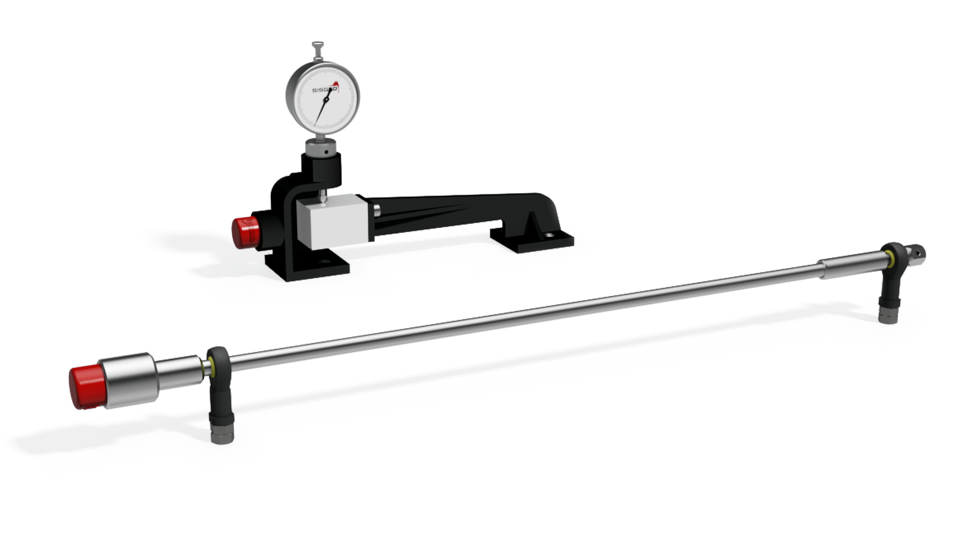

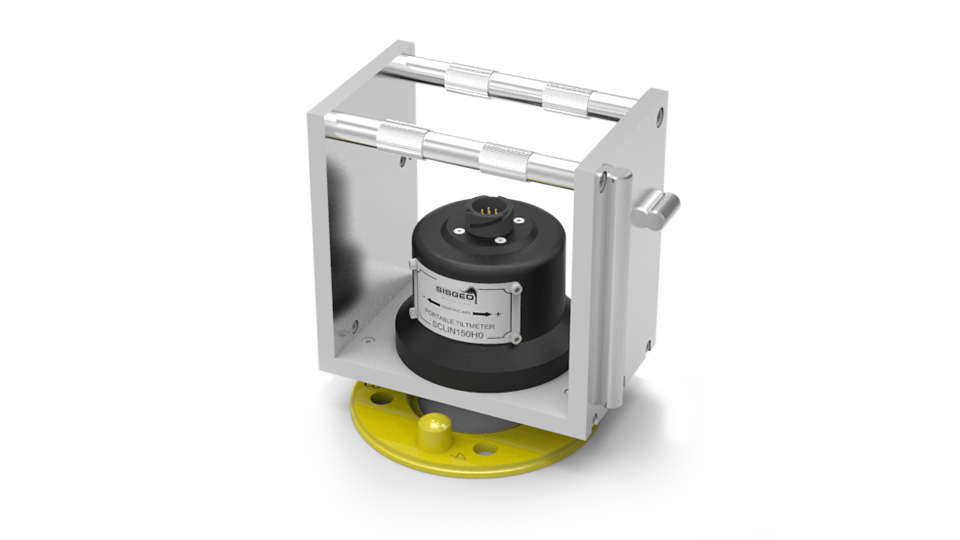

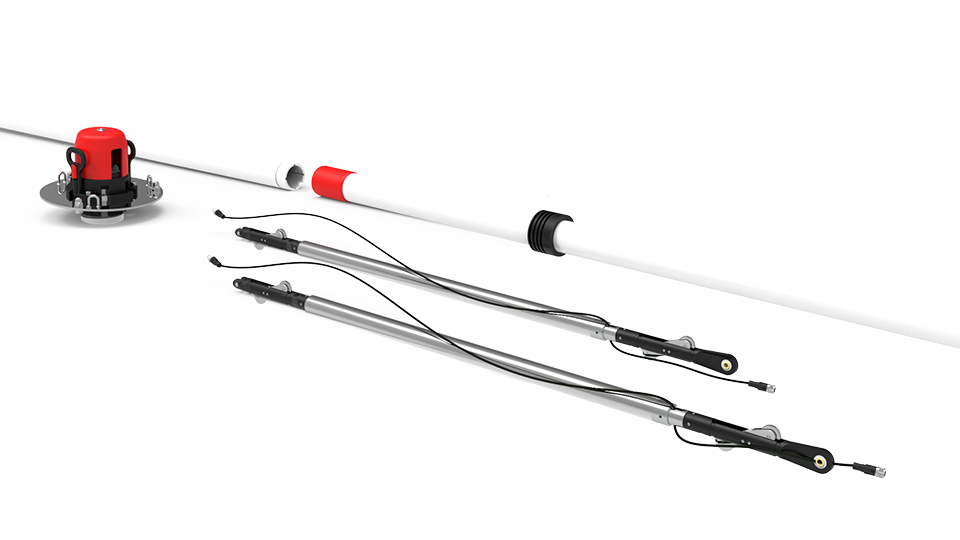

- Tunnel convergence: this refers to the change in the diameter of the tunnel as it is excavated, and is an important indicator of the stability of the surrounding rock or soil.

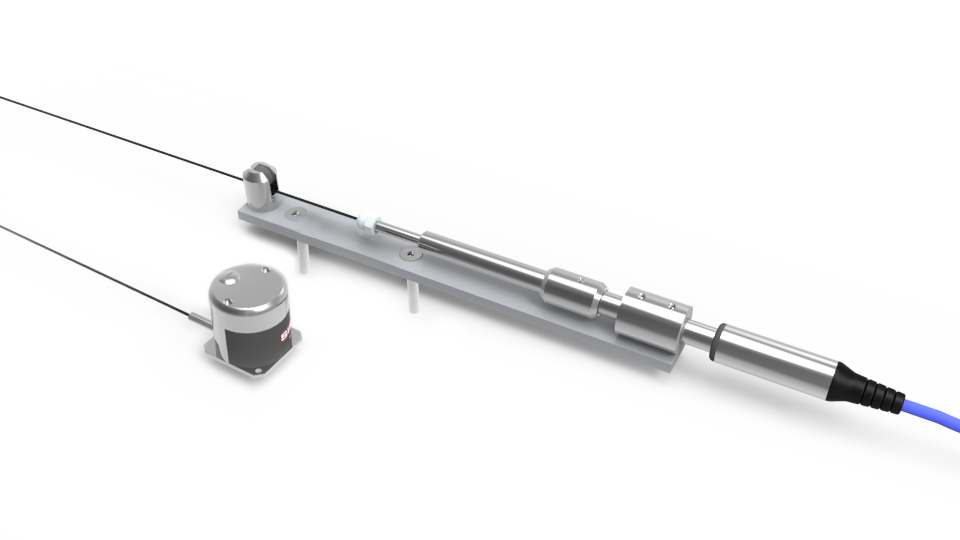

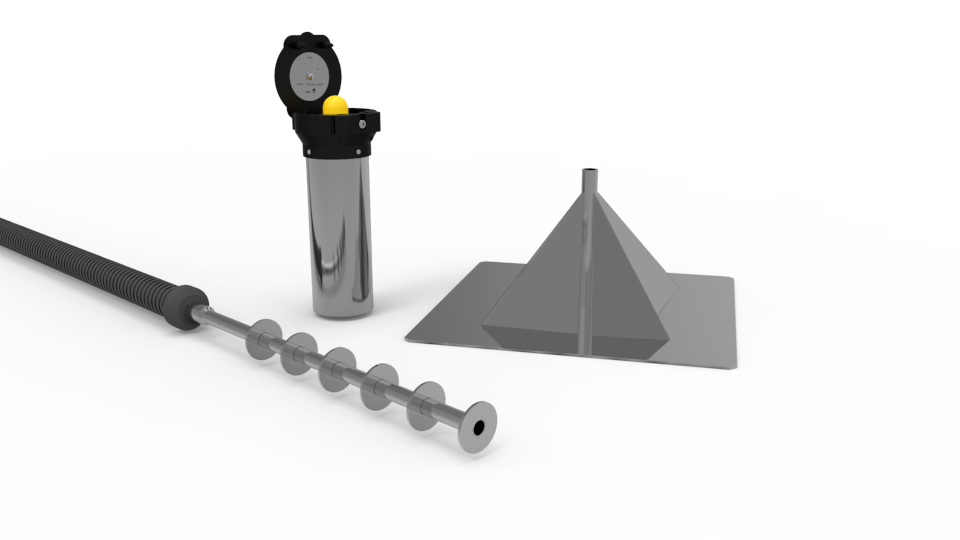

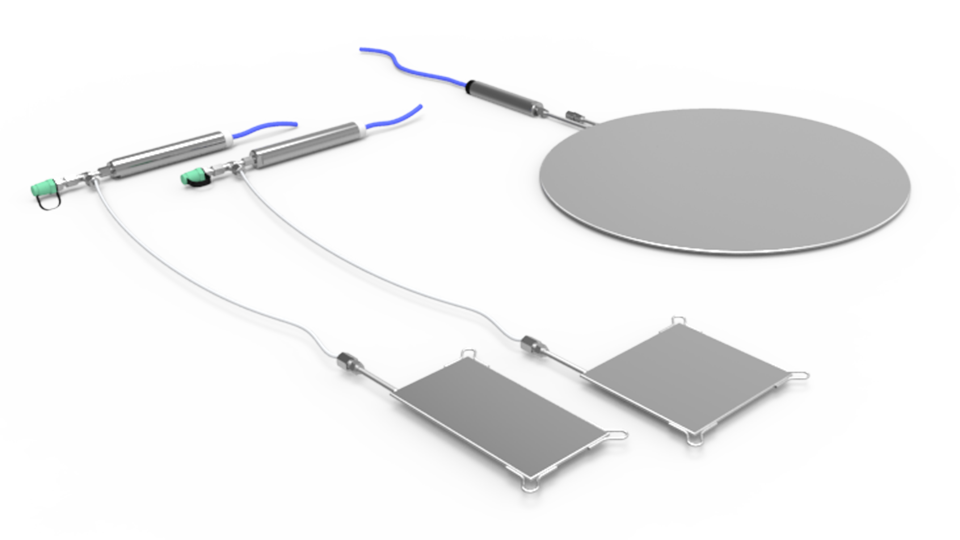

- Ground settlement: this refers to the downward movement of the ground surface due to soil compaction, consolidation, or other factors. Monitoring settlement is important for assessing the stability of the tunnel and identifying potential issues such as differential settlement.

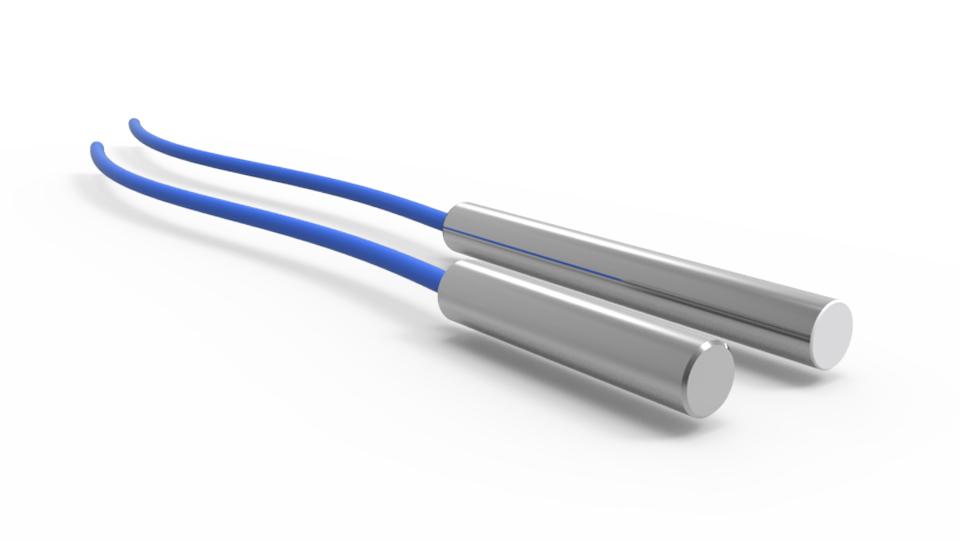

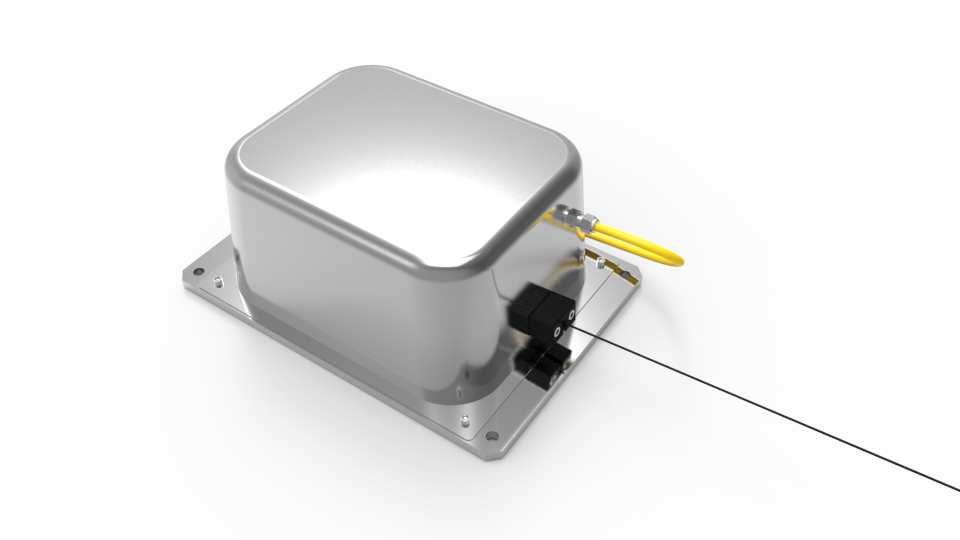

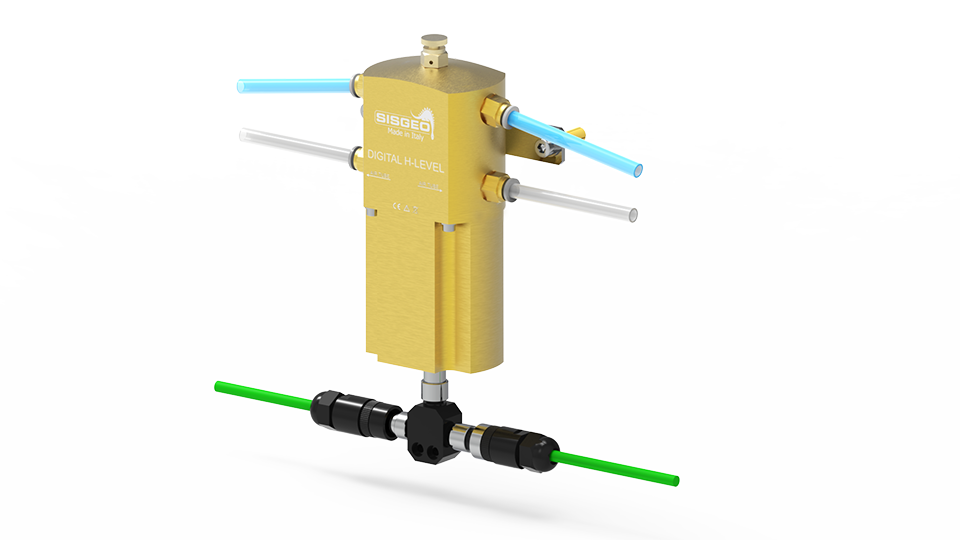

- Groundwater pressure: this refers to the pressure exerted by groundwater on the tunnel walls and surrounding soil. Monitoring groundwater pressure is important for assessing the risk of water infiltration, which can lead to erosion, soil instability, and potential collapse of the tunnel.

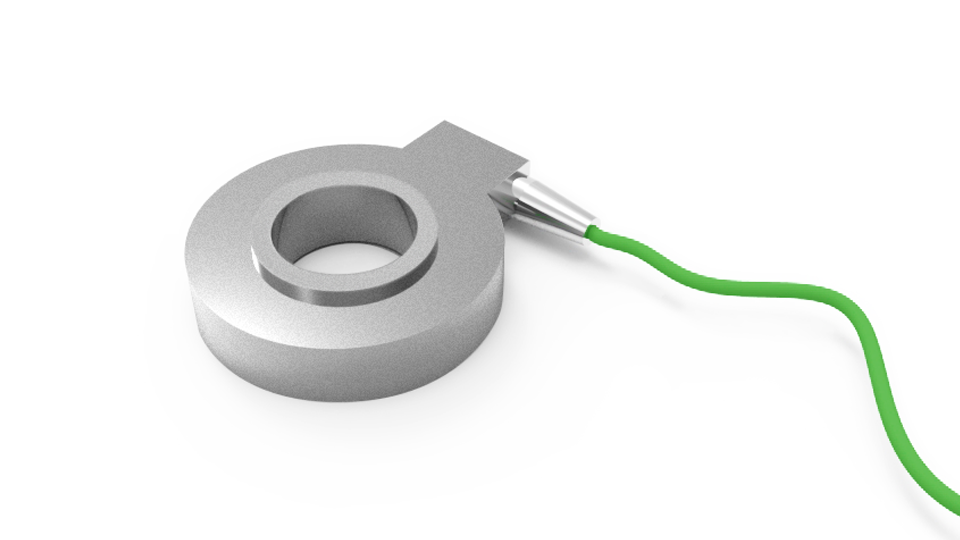

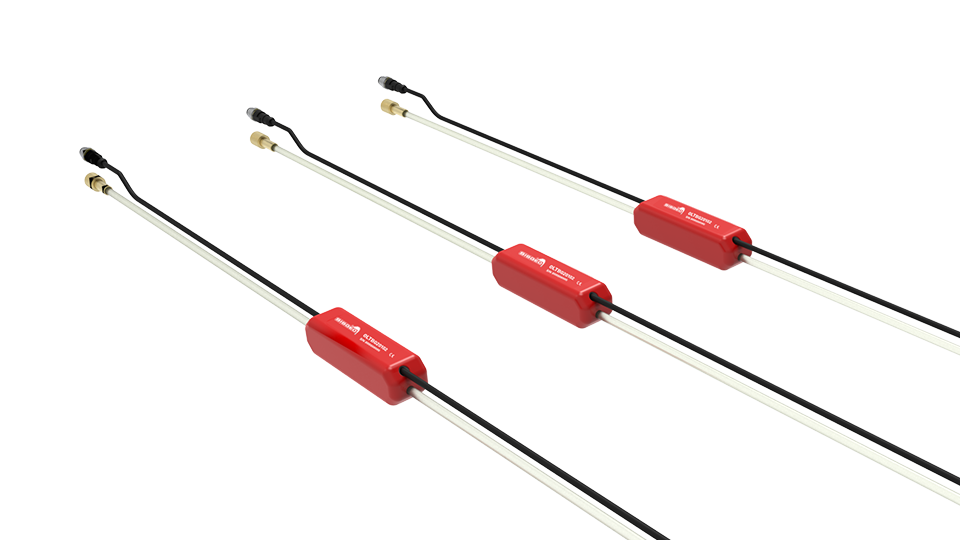

- Rock stress: this refers to the forces acting on the rock surrounding the tunnel, which can affect the stability of the tunnel and the safety of those working within it.

During the operational phase, monitoring is typically focused on assessing the ongoing stability and safety of the tunnel, as well as identifying any maintenance or repair needs. Here are some key parameters that can be monitored during operation include:

- Deformation: this refers to any changes in the shape or dimensions of the tunnel.

- Water infiltration: monitoring for water infiltration is critical to ensure the ongoing stability and safety of the tunnel, and to identify potential maintenance or repair needs.

Overall, NATM tunnel monitoring is essential for ensuring the safety and stability of the tunnel, both during construction and operation. By identifying potential issues early on, monitoring can help to prevent accidents or other safety incidents, reduce maintenance, repair costs, and extend the life of the tunnel.