What is TBM tunnel monitoring?

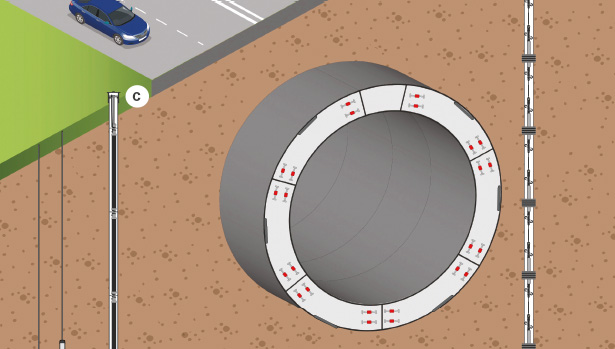

A TBM tunnel (Boring Tunnel Machine) is a tunnel that is build using a massive tunnel drilling machine. During the excavation process, the TBM removes the excavated material from the tunnel face, transports it to the back of the machine, and then transports it to the surface using a conveyor belt system. As the TBM advances forward, precast concrete segments are installed behind the machine to create the tunnel lining.

Constructing a TBM tunnel requires careful planning, design and monitoring, as well as specialized equipment. The tunnel must be designed to withstand the forces and pressures exerted by the TBM, and the excavation process must be carefully monitored to ensure the stability of the surrounding ground and the safety of workers.

During TBM tunneling, several geotechnical parameters should be monitored to ensure the stability and safety of the tunnel excavation process. Some of the main parameters to monitor include:

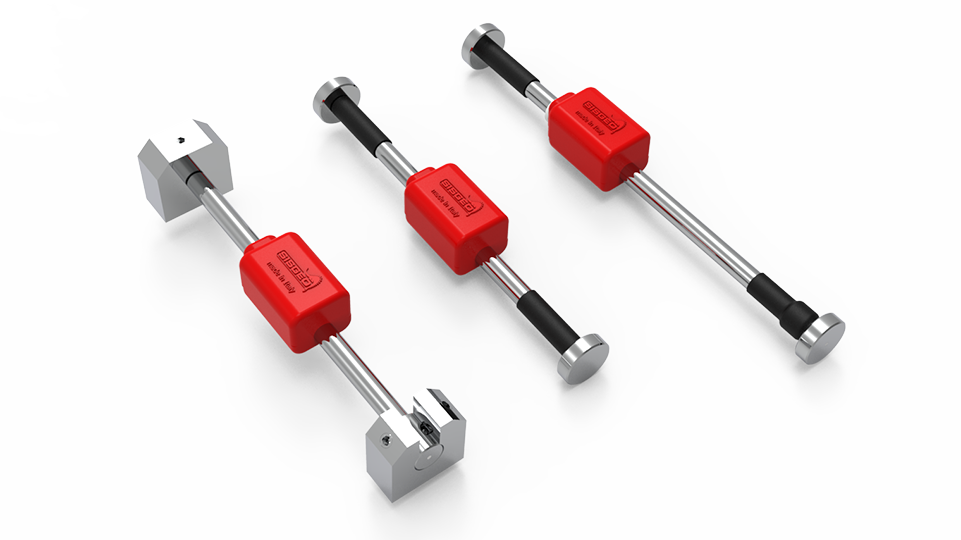

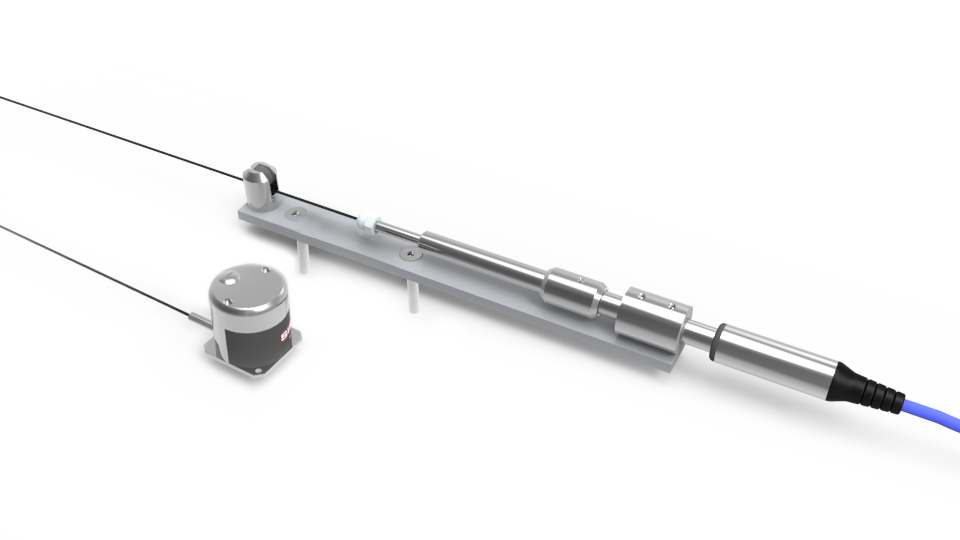

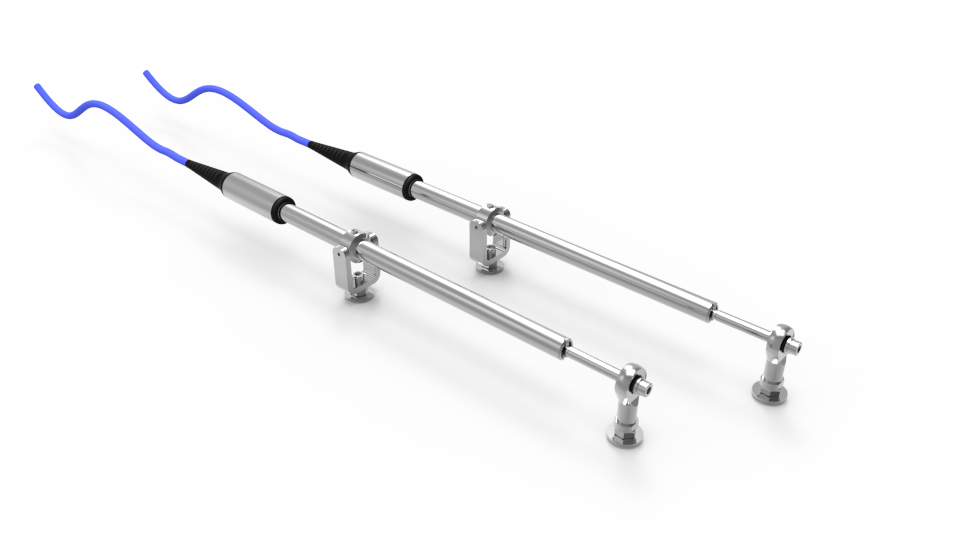

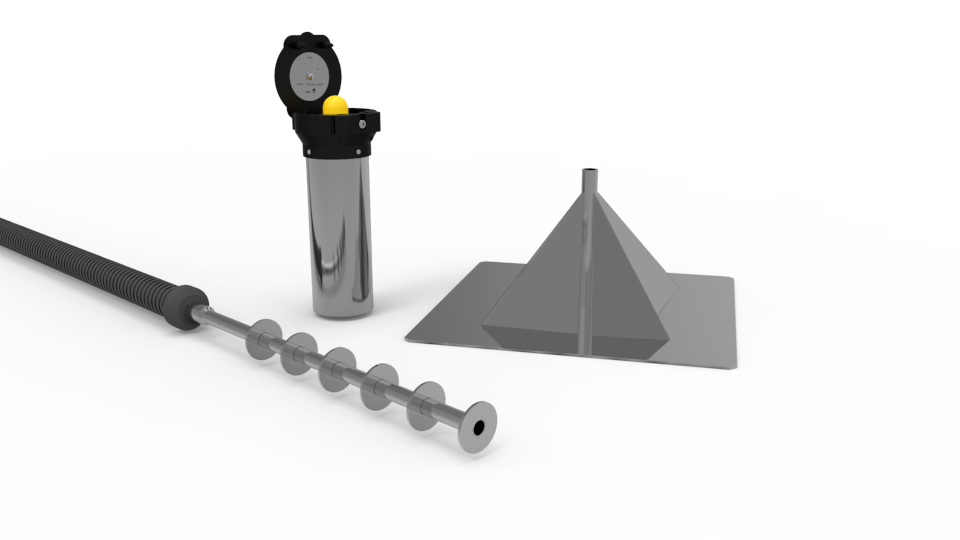

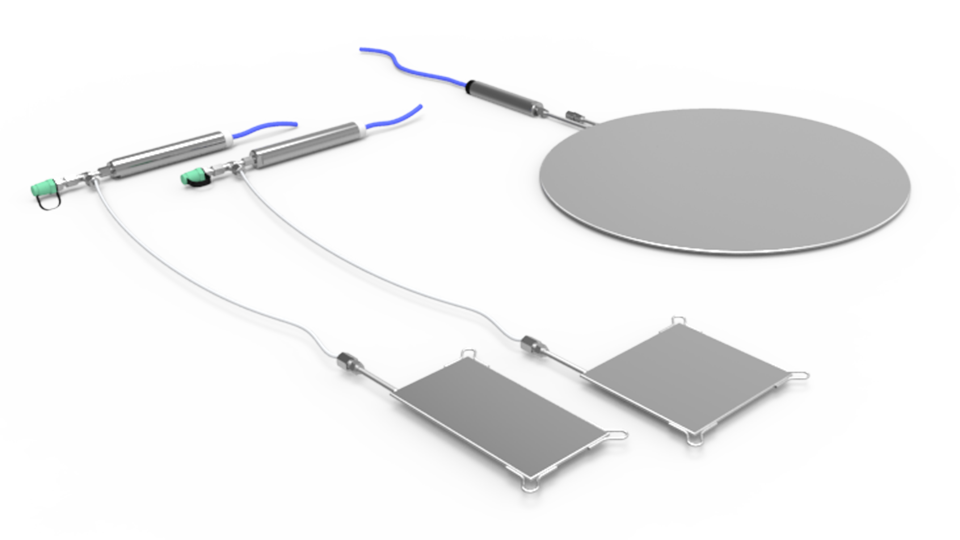

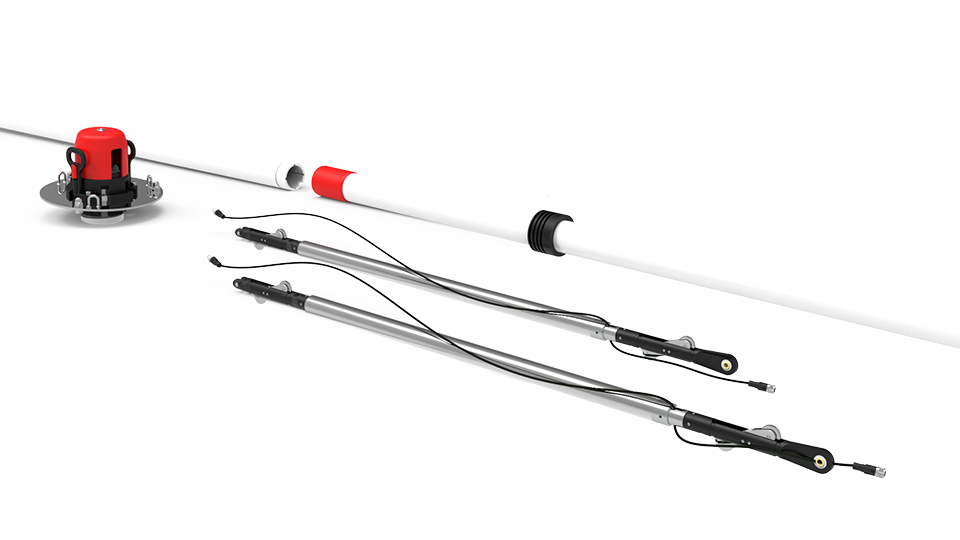

- Ground deformation and settlement: TBM tunnelling can cause ground settlement or heave, which can lead to damage to nearby structures and utilities. Monitoring settlement levels can help ensure that settlement is within acceptable limits.

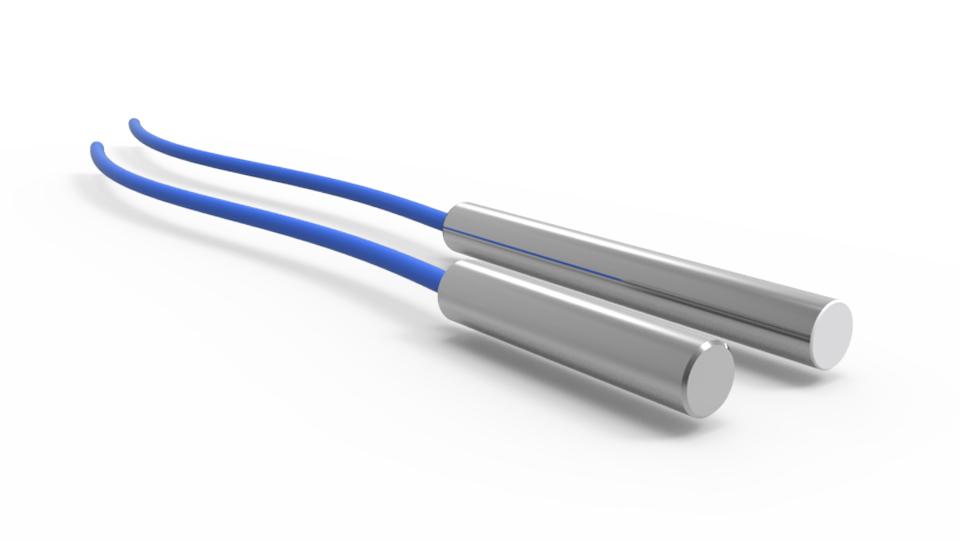

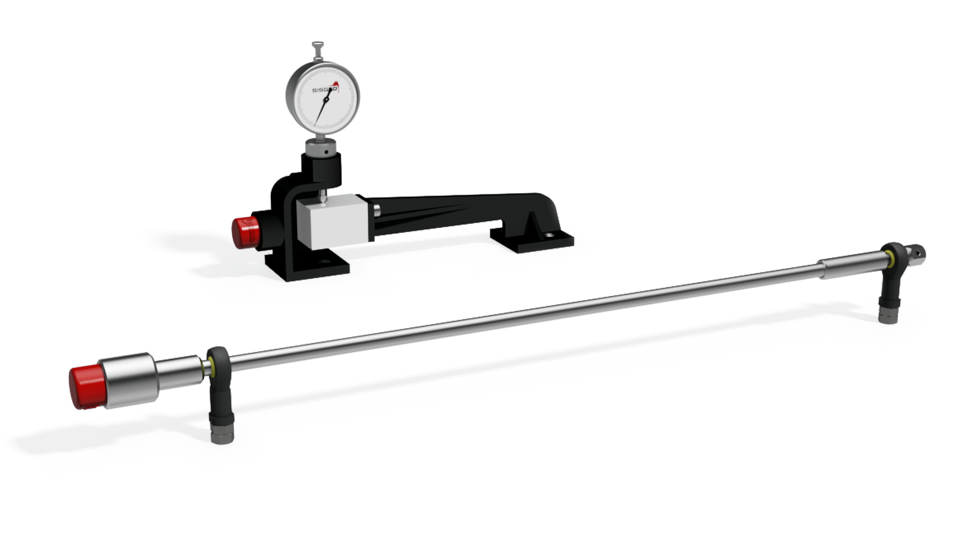

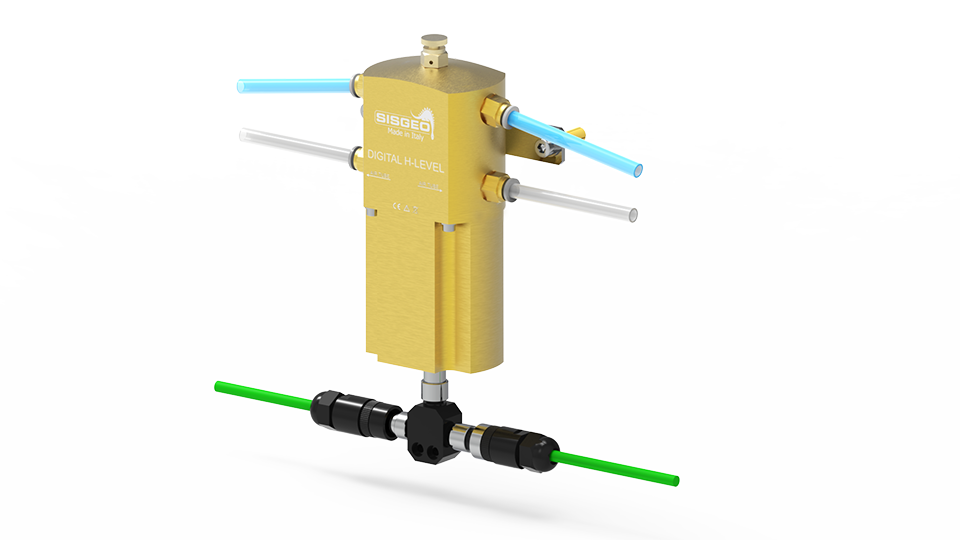

- Groundwater level and pressure: TBM tunnelling can affect groundwater levels, which can lead to flooding and water ingress into the tunnel. Monitoring groundwater levels and pressures can help identify potential issues and allow for the implementation of measures to prevent flooding.

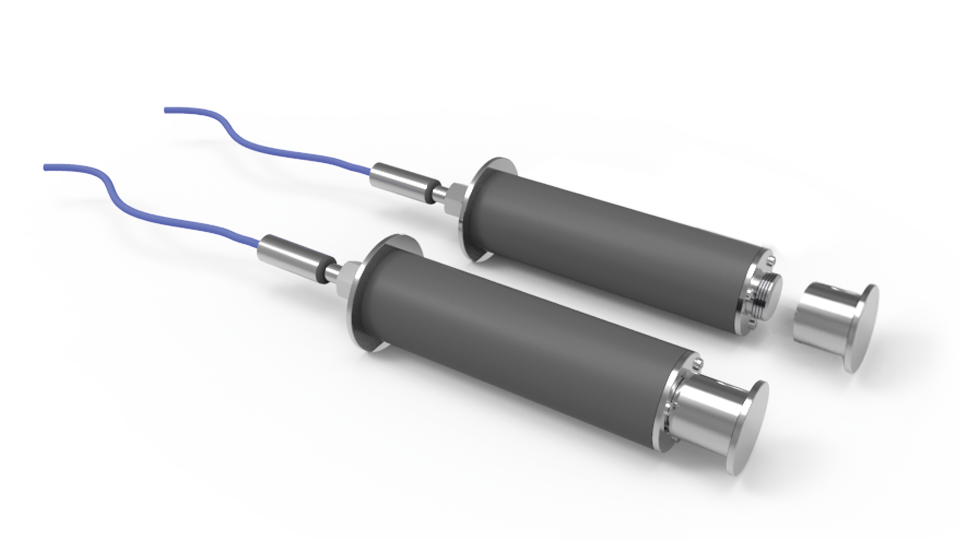

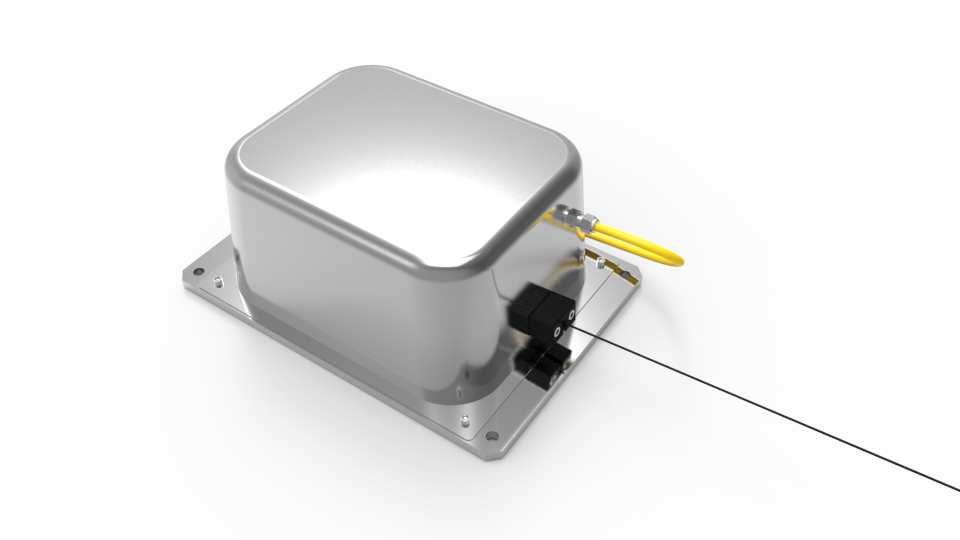

- Soil pressure: TBM tunnelling can cause changes in soil pressure, which can affect the stability of the tunnel excavation. Monitoring soil pressure can help ensure that it is within acceptable limits and allow for corrective measures to be taken if necessary.

- Vibration levels: TBM tunnelling can cause ground vibrations, which can lead to damage to nearby structures and utilities. Monitoring vibration levels can help ensure that they are within acceptable limits and allow for corrective measures to be taken if necessary.

By monitoring these geotechnical parameters during TBM tunnelling, engineers and project managers can identify and address any potential issues that may arise during construction, ensuring the safety and stability of the tunnel excavation process.